|

ROUTING: Preparing for Plastic Routing Part I

This article is the first of

a two-part series designed

to

help fabricators improve

their machining of plastics.

When companies make the

transition from the routing

of wood or aluminum

to the machining of plastics, there are

a number of preliminary procedures

and considerations that can help

ease the conversion and ensure a

smooth transition.

Periphery factors in the routing of

wood and aluminum can become some

of the most significant aspects of plastics

machining. Good planning and

preparation can help ease these factors

and the costs associated with the

startup of a new machining process.

This article is the first of a two-part

series that discusses the need to

have active preparation when making

the transition from wood routing to

plastic routing. Part 1 discusses the

CNC router and its associated hardware.

Part 2 will discuss tooling and

material selection.

Preparation of the

CNC Router

Routine maintenance of CNC

routers is a critical factor for ensuring

a high level of precision and repeatability

in finished parts. These maintenance

operations are defined by the

router manufacturers and are

absolutely essential when plastic

parts are to be machined. Minor

spindle vibration, gantry or bridge

shake and servo positioning errors

frequently have minor or unnoticeable

impacts in wood but can result

in scrap or expensive finishing operations

in plastic. The severity of these

problems is the direct result of

machine quality and adherence to

the manufacturer’s recommended

maintenance schedule.

Besides preventative maintenance,

there are additional steps that fabrication

companies can take to help

ensure a successful first run. Listed

below are some recommended actions

to consider before machining plastic.

Runout

The spindle, spindle mount and colleting

system should be checked for

the amount of TIR (Total Indicator

Runout). Tools required for verifying

TIR are: 0.001 inch or better dial

indicator,

a magnetic indicator base,

a 6 inches or longer indicator stand

assembly and a long shank solid carbide

tool, a blank drill rod or blank

solid carbide round.

a magnetic indicator base,

a 6 inches or longer indicator stand

assembly and a long shank solid carbide

tool, a blank drill rod or blank

solid carbide round.

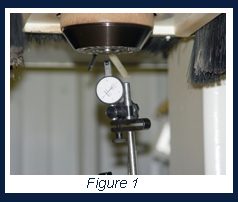

The first verification should be

made inside the spindle taper (see

Figure 1). The router or spindle manufacturer

should be able to provide

you with an acceptable upper limit for

TIR. An acceptable value is typically

0.001-inch TIR or better on older spindles and 0.0005-

inch TIR or better on newer spindles. There should be no

play in the radial direction of the spindle at any time.

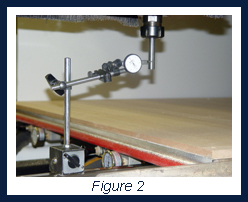

The second verification

should be with a rod inserted

into the collet (see Figure 2). Measure the TIR at the furthest

point from the spindle. This measurement needs to

be taken multiple times with the rod being re-chucked and

rotated after each measurement. TIR is an additive property

and can vary depending on how the taper, collet,

chuck nut and rod align. The maximum reading is an indication

or true TIR. The colleting system should be better

than .002 inch total TIR for older machines and 0.001 inch total TIR for newer machines.

should be with a rod inserted

into the collet (see Figure 2). Measure the TIR at the furthest

point from the spindle. This measurement needs to

be taken multiple times with the rod being re-chucked and

rotated after each measurement. TIR is an additive property

and can vary depending on how the taper, collet,

chuck nut and rod align. The maximum reading is an indication

or true TIR. The colleting system should be better

than .002 inch total TIR for older machines and 0.001 inch total TIR for newer machines.

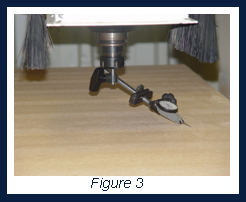

The third verification is dependent on whether the routing

involves any surface milling, pocketing or lettering. If

these operations are performed and require a high degree

of surface finish, the spindle should be verified perpendicular

to the work surface. This typically involves removing

any spoilboards and setting the indicator as shown in

Figure 3. By finding the amount of tilt the spindle mount

has in both the X and the Y-axis, it is possible to determine

the degree of apparent machining marks that will be

seen on the bottom of a pocket cut.

Once the dial indicator is mounted in the spindle and

zeroed on the main table surface, rotate the spindle 180° by

hand and record the amount of TIV (Total Indicator Variance)

along both the X and Y-axis. The larger the TIV, the more

delineation will be seen during parallel pocketing cuts. This

effect is exaggerated by the use of larger diameter tools.

any spoilboards and setting the indicator as shown in

Figure 3. By finding the amount of tilt the spindle mount

has in both the X and the Y-axis, it is possible to determine

the degree of apparent machining marks that will be

seen on the bottom of a pocket cut.

Once the dial indicator is mounted in the spindle and

zeroed on the main table surface, rotate the spindle 180° by

hand and record the amount of TIV (Total Indicator Variance)

along both the X and Y-axis. The larger the TIV, the more

delineation will be seen during parallel pocketing cuts. This

effect is exaggerated by the use of larger diameter tools.

Collets

All collets and collet mating surfaces should be examined

and cleaned. Well-used collets should be considered

for replacement even if they are not showing obvious signs

of wear.

The following are collet replacement time recommendations:

- After 400-600 hours of runtime.

- A tool has broken in the shank.

- A tool has spun in the collet.

- A tool has been “short shanked” within the collet.

- The collet has been sprung.

Unlike the machining of wood where collet condition typically

has the greatest effect on tool life and breakage, collet

condition becomes apparent much sooner in plastics

machining where the product’s edge finish rapidly deteriorates.

There are specially designed felt and brass brushes

shaped for cleaning the insides of tapers and collets, and

these should be used during every shift change, every manual

tool change and every time a collet is changed.

There are various chemical cleaning products available for

routine collet maintenance, and they do a good job of removing

buildup that brushes cannot always eliminate. Petroleum

products should be avoided due to their ability to attract and

trap dust within the colleting system. Alcohol, citrus cleaners

and other formulations are good alternatives.

Vacuum

Vacuum systems should be evaluated for their ability to

hold small or thin parts. Many plastic sheet parts and/or

thermoformed parts are much more difficult to hold due to

their size, shape and comparably light weight. By taking

steps to increase the amount of usable vacuum, fabricators

can reduce the amount of time spent on custom fixtures and

typically achieve higher feed rates with better cycle times.

Flow through systems should be evaluated for: -

Pump Size - 800 cfm or greater for a 4-foot by 8-foot

table.

-

Spoilboard - lightweight, porous MDF with a reasonable

thickness and the edges sealed to reduce air leakage.

- Supply Lines - evaluate for diameter and quantity. Flow

through systems benefit greatly from multiple large

diameter supplies. Consider using two or more 4-inch or

larger supply lines for each table.

Discreet (or dedicated) systems should be evaluated for:-

Pump Size - 25 in Hg or better vacuum at full sealed

vacuum conditions.

-

Spoilboard - should be channeled to provide best vacuum

dispersion and sealed all around to prevent leaks.

- Supply Lines - multiple 1/2” diameter or larger lines are

recommended.

Dust Collection

It is possible to have both too much and not enough

dust collection at the same time. Dust collection systems

serve two purposes: to remove the chips from the work

area and to keep the spindle and tool cool. Dust collectors

that are under-powered can reduce spindle life and produce

poor quality finishes by not extracting chips from the

cut path. These chips and their associated heat can ruin

otherwise acceptable finishes. Over-powered dust collection

with rigid dust brushes can overwhelm vacuum hold

down fixtures for small parts and cause part movement or

part ejection. Care should be given to the evaluation of

the role of the dust collector for each job.

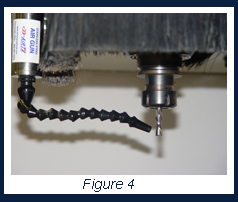

Coolant

While mist or liquid coolants typically are an

unacceptable addition for most CNC plastic routing

applications, air coolant systems should be seriously

considered. A simple air nozzle (see Figure 4)

directed at the cutting bit can dramatically improve

cut quality and tool life. The air serves to cool the

tool and cut path, remove warm chips, and reduce

the instances of chip wrap around the cutter.

unacceptable addition for most CNC plastic routing

applications, air coolant systems should be seriously

considered. A simple air nozzle (see Figure 4)

directed at the cutting bit can dramatically improve

cut quality and tool life. The air serves to cool the

tool and cut path, remove warm chips, and reduce

the instances of chip wrap around the cutter.

Another option is to use a cooling nozzle. These

devices go by various names (cool gun, cold gun,

Venturi gun) and use a Venturi orifice to significantly

reduce the temperature of the air flowing

from the nozzle. By using chilled air, cutter life and

cut quality can be considerably extended. A drawback

is that the velocity of the air is significantly

reduced. This reduces the ability of the nozzle to

remove chip wraps and requires that it be placed

closer to the router bit to overcome the air dispersal

associated with the dust collector.

By evaluating the above machine factors before

beginning a plastic routing operation, the chances

of success and profitability can be significantly

improved.

The next article will cover the topics of tool selection

and material selection before actual machining

takes place.

For more information, click on the author biography at the top of this page.

|