|

ROUTING: Routing Polyethylene

Polyethylene is a widely utilized plastic in the thermoforming

and sheet fabrication industry. These

manufacturing processes involve secondary routing

operations to produce the end product. Part of the

popularity of this material can be attributed to how easily

it is routed when proper cutting

tools and procedures are a part

of the manufacturing process.

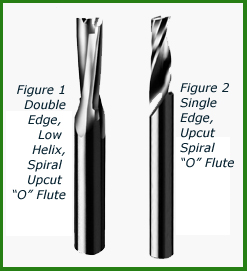

Plastic is generally classified as

soft or hard for routing purposes.

Polyethylene falls on the soft

side of the equation and mostly

utilizes “O” flute geometry routing

tools.

These tools are available

in straight and spiral configurations

with single- and double-edge

cutting

capability.

(See Figures

1-4). The

choice of

straight versus

spiral

tooling

becomes a

function of

how the chip

needs to be

influenced.

Straight tooling

has a neutral

effect, while

spirals can

move chips in

an upward or

downward

direction.

These tools are available

in straight and spiral configurations

with single- and double-edge

cutting

capability.

(See Figures

1-4). The

choice of

straight versus

spiral

tooling

becomes a

function of

how the chip

needs to be

influenced.

Straight tooling

has a neutral

effect, while

spirals can

move chips in

an upward or

downward

direction.

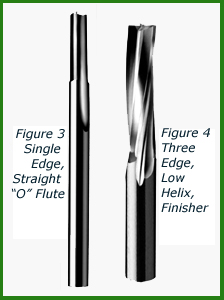

In most

instances, the

thermoformershould choose

straight “O”

flutes, while the

sheet fabricator

should rely on

spiral upcuts.

When the part is held solidly, these tooling choices accommodate

the removal of chip without adversely moving the

part being routed. Most “O” flutes in the marketplace are

single-edge because they provide increased

chip clearance

capability without sacrificing edge finish.

chip clearance

capability without sacrificing edge finish.

Double-edge tools usually become a part of the routing

process when more refined edge finish is required or tool

balance is an issue.

Beside the type of tool selection, tool diameter is always

a critical issue. Plastic fabricators, particularly sign makers,

tend to use small tool diameters because of small radii and

material waste considerations. However, with a softer

material like polyethylene, larger tool diameters can play a

positive role. The larger the diameter, the more flute space

is available to remove gummy chips. Also, the larger diameter

provides more stability and increased benefits fits in the area of better edge finish. Larger diameters are beneficial,

but the end-user should be cautious in this area, as

well. Single-edge tools should never be applied in a CNC

machine in diameters over 3/8 of an inch. These tools in

larger sizes can create out-of-balance issues. When larger

than 3/8 is required, double-edge tools should be utilized.

These tool selection ideas are general in nature and provide

a good starting point for decision making in this area.

In order to enhance this process, the end user can visit

www.plasticrouting.com or any number of tooling or manufacturing

sites to get specific tool recommendations on

polyethylene and a variety of other plastic materials.

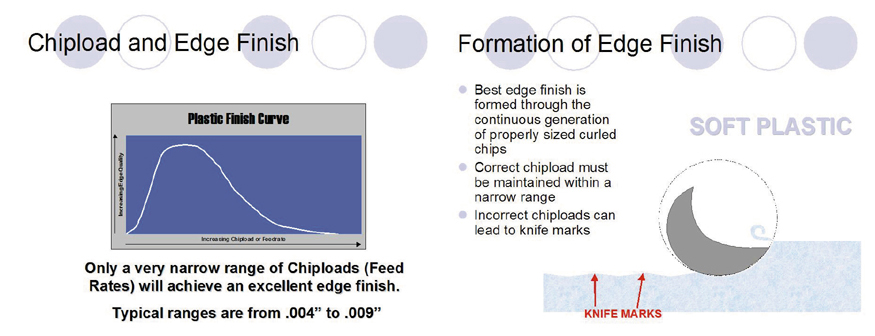

Polyethylene, like most soft plastics, will produce a curled

chip. The range of chipload to produce and maintain a

properly curled chip is somewhere between .004 and .009.

Chipload is actually the thickness of the chip, and is a function

of the feed rate and the spindle speed of the CNC routing

machine. The size of the chip has a direct correlation on

the edge finish and the ability to adequately remove soft

chips (See Figure 5). When chiploads get too far outside the

recommended range, the tool or knife marks are more

prevalent, thus adversely affecting edge finish (See Figure

6). Conversely, when chiploads become too small, the ability

to clear chips without melting becomes problematic.

Consequently, it is imperative to maintain a fairly narrow

range of chipload to maintain both of these parameters.

Polyethylene is a mainstay in the plastic fabrication

industry. It is one of the easiest plastics to cut, but only

when the proper tool selections and chipload requirements

are met.

For more information, click on the author biography at the top of the page.

|