|

WRENCHLESS ROUTER COLLET

Short-run fabrication pieces, such as custom point-of-purchase display components, require a router user to change bits frequently, adding significantly to the overall length of the job. A new accessory by Jacobs® Chuck Manufacturing Co. reduces the time it takes to change router bits, thus increasing overall productivity. "The PowerCollet" allows router users to change bits by hand. By replacing a router's conventional collet and nut, plastics fabricators can change router bits in seconds instead of minutes, said Nancy McCarthy, Group Brand Manager of Jacobs, a subsidiary of Danaher Corp.

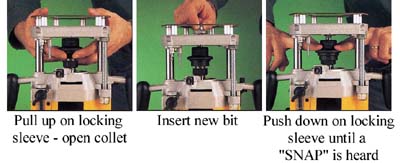

"Whether you use a table-mounted router, pin router or hand-held router, the user simply pulls up on the locking sleeve to open the collet, inserts the new bit and pushes down on the sleeve until a 'SNAP' is heard," said McCarthy. "The PowerCollet provides a safe, secure grip for use under the toughest routing conditions. And its toolless solution means no more banged knuckles with stubborn wrench-style collets."

"I definitely like the concept of a quick-release collet because we do so many jobs that entail a lot of changing of bits," said Thomas R. Burns, President of TRB Plastics, a plastics fabrication, prototyping and production shop. "It's irritating to change bits so often, primarily because it takes away from the real work you are doing. I'm also concerned about the safety of the people running the machines. I've had times where the router bits are not tightened properly and it's spinning at 20,000 RPMs. That is a fear factor. With this product, if you hear the SNAP, you know it is secure and the fear factor is eliminated."

Added Burns, "For parts that are shaped anything but rectangular, we use a trim bit and template to guide the part to be cut into the odd shape. For short-run production, where we change bits constantly, the PowerCollet is a lot quicker than getting in there with wrenches. This product is more of a time-saver than anything. It is fast and convenient."

The collet is precision engineered to ensure smooth router operation, and is sealed from contamination. It can be used in hand-held or table-mounted applications and fits most 1/2" routers. The 1/2" capacity will also accept 1/4" bits with the use of a 1/4" step down bushing.

For more information, contact John Timson, Danaher Tool Group, 805 Estelle Dr., Box 3767 Lacaster, PA 17604-3767, 800-866-5753, 717-898-6540, FAX 717-898-8360, www.jacobschuck.com

|