|

CUSTOM AND NEAR-NET-SHAPE NYLON CASTING

The advantages of cast nylon are well known: toughness, strength, relative low cost, large-size capability, and good wear properties. Cast nylon is available in grades that accentuate one or more of these properties. Additives for wear resistance, impact strength, and surface hardness are typical. Certain additives and processing techniques result in materials, such as VEKTON® 6XAU, which operate in higher long-term temperature applications without the degradation common with standard cast nylons.

What is cast nylon 6? - It is a semi-crystalline polymer formed by the polymerization of caprolactum. This polymerization occurs in a heated mold after the introduction of a catalyst and an activator via two liquid streams. Additives are introduced to the streams before they are combined in the mold. Because the material is being chemically formed in the mold, large shapes and parts can be made with less stress as is associated with shrinkage in large injection molded parts. Pieces are then stress-relieved to further minimize any cast-in stress.

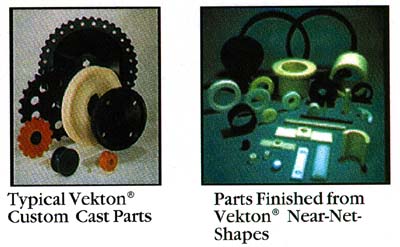

What is custom or "near-net-shape" casting? - Custom casting is the term for producing non-standard shapes in a mold that creates most of the details or features that would typically be machined. For example, a wheel with side contours, ribs and a track groove could be custom cast so that only the bore would need machining.

Customers typically pay for these custom molds and therefore maintain exclusive rights to any pieces produced from them.

Near-net-shape casting refers to producing a part that contains a few of the details of the desired finished part in order to reduce the material and machining labor costs. This is simply a form of custom casting, which would require the creation of a mold to "cast-in" the near-net-shape detail and allow for enough material to do the finish machining.

What makes a part a candidate for custom or near-net-shape casting? Based on annual volume, Ensinger typically looks at parts between 3 and 1200 pounds. For parts in the 3-pound range, an annual volume of 1,000 or more may be necessary to make it a valid candidate. For parts weighing close to 1200 pounds, one a year may suffice! Since mold costs can range from a few hundred dollars to thousands of dollars, Ensinger analyzes the annual volume, the material saved, the machining labor saved, and the mold cost, to determine feasibility. All candidates should be considered, as this analysis is quick and simple.

What kind of tolerances can I expect on a custom cast part? This question usually causes the most problems when converting from a machined component to a cast part. Nylon casting results in parts that vary somewhat due to atmospheric conditions, the reactivity of the chemicals used and normal variations in a production environment. The end result is a part that is typically + or - 1%, or 1/32", whichever is greater, on most dimensions. Many times certain critical dimensions can be held to a tighter tolerance. In most cases the part can be designed to function properly or, if not, be machined to the required tolerances.

Applications - Custom cast nylon parts should be considered for any larger size nylon parts, and many times as a replacement for cast aluminum, bronze, stainless steel, or phenolic parts. Advantages based on material properties, mold economics, part consolidation, and reduced weight make cast nylon parts ideal for many applications using these materials. Performance specifications must be analyzed before substitution is made. On occasion, custom cast nylon parts compare favorably in price to larger machined UHMWPE parts due to reduced machining and material savings.

For more information, contact Ensinger, Inc., 365 Meadowlands Blvd., Washington, PA 15301, 800-243-3221, 724-746-6050, FAX 724-746-9078.

|