|

ROUTING: Routing & Fixturing ABS

The fixturing

method, feed rate

and chip flow control

can determine

the

type of tooling used

when machining

ABS.

ABS is one of the most popular plastics

used by thermoformers

and rotational molders. It is

also one of the most versatile,

from low-density foam to highdensity

material. It has been

used in consumer products for

years and is becoming the

material of choice in many auto

and truck components.

ABS combines toughness, stability,

wide temperature range and

chemical resistance with relative ease

of fabrication. That, combined with its

low water absorption and high to low gloss

range in a variety of colors, often makes it the plastic

formula of choice for a wide range of

applications.

Instrument panels, headliners,

grilles, wheel covers, decorative

trim, mirror housings, truck bed

liners and bumper farings are

some of the applications in

which ABS has been used successfully.

Small and large appliances,

refrigerator door liners,

business machine and electronic

housings, luggage, toys, storage

bins and flower pots also made from

ABS are often trimmed by air or CNC

routers. Pipe and fence materials made from

ABS are used in several products requiring unique

routing methods.

Using a Spoilboard

ABS is a reasonably-priced material

and can be machined in a most

cost-effective manner. While the

substantive properties of this material

would often dictate restrictive

machining practices in other formulations,

this is not the case with

ABS. There are just a few — but

important — considerations when

routing or trimming ABS.

In many instances, CNC routers are

set up with the right tools and an

elaborate vacuum system. The spoilboard,

however, is overlooked and

becomes the problem area. The one

thing that can make or break an ABS

setup is the ability to hold a part on

the table “rock solid.” ABS parts are

normally quite flexible and will tend

to vibrate if not fixtured properly.

There are many elaborate pod systems

employed by both point-topoint

machines and routers. These

systems can be very effective. There

are also many machines utilizing

dedicated spoilboards to hold parts.

This is most often the case with ABS

parts. The proper way to build a dedicated spoilboard is often misunderstood or cut short, in

the interest of time. Taking the time to do it right will pay

dividends in the form of productivity and piece part finish.

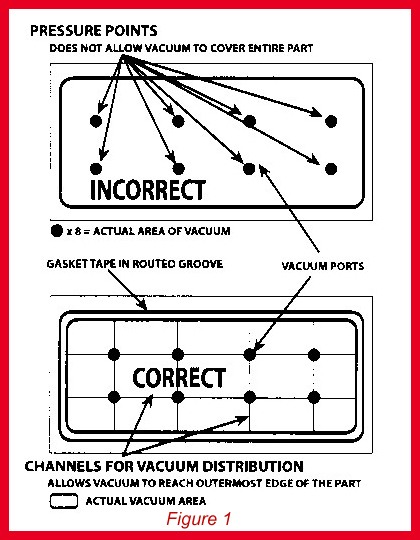

Many people consider a spoilboard a piece of MDF or

particleboard with self-stick weather-stripping and a few

holes drilled inside the perimeter. While this type

of fixture may work in a few instances, it does not

often satisfy the demands made in high-performance

routing. If a router is going to run at production

speed, the parts must not move. The preferred

spoilboard technique employs grooving the

interior area of the gasket perimeter to allow a

vacuum to reach the outermost portion of the

part. The holes are then drilled at the intersection

of the vacuum grids.

The method provides a

greater vacuum surface area. It is preferred to

just drilling holes in the spoilboard because it provides

a “bead” of vacuum to the outermost edge

of the part, giving the best chance for a “rock

solid” hold. (Figure 1)

Tool Selection

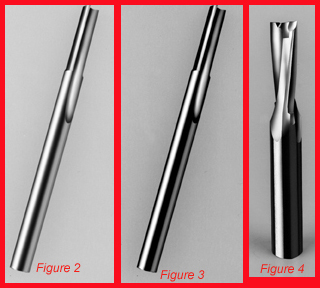

Once the ABS has been properly fixtured, tool

selection is a straightforward process. The router

bit of choice for most thermoformed sheet, 6mm

or less, is the O flute tool, either single or double

edge.

In many instances, the part can be machined

while cooling. High-speed steel tools work very

well in this instance. (Figure 2) In all instances,

ABS can be trimmed and routed effectively with solid carbide O flute tools. (Figure 3)

A newer product in solid carbide router bits for plastic applications is the O flute spiral

tool. (Figure 4) While available for many

years in straight or shear geometry,

recent developments in CNC grinding

technology has enabled the design and

manufacture of the O flute spiral,

which provides for better chip flow

control in certain applications.

Reweldment

One of the few problems in

machining ABS can be chip

reweldment. This occurs when

the chip is not removed properly

or quick enough. It can

also occur when the feed rate

is too slow.

While these problems can

be easily resolved in a CNC

environment with proper fixturing

and tool selection,

they can be more difficult to

solve in hand-held or air routing applications.

Depending on the difficulty of the setup, fabricators

may want to consider using carbide-tipped

straight flute tools if high speed steel

does not provide satisfactory tool life. (Figure 5)

In these situations, carbide-tipped tools may be

preferable to solid carbide because of the

strength of the tool steel body. Whether the

router is CNC or hand-held, ramp entry into the

ABS workpiece — rather than straight plunge

— will also prevent rewelding.

Depending on the difficulty of the setup, fabricators

may want to consider using carbide-tipped

straight flute tools if high speed steel

does not provide satisfactory tool life. (Figure 5)

In these situations, carbide-tipped tools may be

preferable to solid carbide because of the

strength of the tool steel body. Whether the

router is CNC or hand-held, ramp entry into the

ABS workpiece — rather than straight plunge

— will also prevent rewelding.

In any plastic routing application, fabricators should

experiment with both single- and double-edge bits, as

well as both spiral and straight flutes, to determine the

best tool for the specific job.

For more information, click on the author biography at the top of this page.

|