|

AWFS® New Products

AWFS®Vegas, held in Las Vegas Nevada July 27-30,

2005, hosted buyers from the entire U.S. and 53 countries.

Nearly 20,000 attendees browsed 898 exhibits featuring

a wide array of new products. Following is an

overview of some of the new products we found that are

well suited for the needs of plastic distributors and fabricators.

Also see New Products beginning on page 24 and

Literature Review beginning on page 36 for more new

machinery and tooling to help your business be more productive

and more profitable.

Compact Panel Saw

A redesigned vertical panel saw now available from

Colonial Saw offers improved precision and convenience

over previous models.

The Swiss-made Striebig

COMPACT is the only saw of its kind to feature standard

aluminum fingers that can be moved individually along

the horizontal T-slotted center shelf bar to customize the

saw. For greater comfort when sawing small panels, the

workpiece support is provided along the full length of the

saw. Other user-friendly improvements include a shifting

grid that moves upward so that it can’t be jammed or

damaged by off-cuts leaning against the frame, a 24”

repetitive rip device with a roller follower and a measuring

stop that flips out of

the way.

The Swiss-made Striebig

COMPACT is the only saw of its kind to feature standard

aluminum fingers that can be moved individually along

the horizontal T-slotted center shelf bar to customize the

saw. For greater comfort when sawing small panels, the

workpiece support is provided along the full length of the

saw. Other user-friendly improvements include a shifting

grid that moves upward so that it can’t be jammed or

damaged by off-cuts leaning against the frame, a 24”

repetitive rip device with a roller follower and a measuring

stop that flips out of

the way.

The new COMPACT

is a freestanding, rigid

unit that can handle

sheets up to 5’ x 10’. It

cuts perfect, repeatable

edges on particleboard,

acrylic, composite,

plastic and non-ferrous-

metal panels. There is additional dust extraction, and a

new plunge-handle “telescopes” to facilitate the ripping of

tall panels. Other performance-enhancing features include

heavy-duty support rollers and adjustable cutting depth.

Improved digital measuring systems provide increased

accuracy and convenience. The X-axis system permits fine

adjustment for accuracy to 1/10 mm and has a long-life

battery. The Y-axis system allows toggle-switch referencing

from the saw’s rollers or center shelf. Other options

include a scoring saw unit, grooving accessories and an

angle-cutting unit. All components are UL/CSA approved.

For additional information, contact David Bull, Colonial

Saw, Inc., 122 Pembroke Street, P.O. Box A, Kingston,

MA 02364, 781-585-4364, Fax: 781-585-9375, E-mail:

info@csaw.com, Web: www.csaw.com.

Router Line

Hendrick/RWH Industries, Inc. manufactures a full line

of high speed 5-axis CNC routing/trimming machines.

Both moving table and moving gantry styles are available.

Options include single- or dual-tables with vacuum or Tslot

clamping and automatic tool changing. Windows

based PC controller with full 5-axis simultaneous control,

network and remote diagnostics capability with 5-axis

program teaching pendant are standard features.

Options include single- or dual-tables with vacuum or Tslot

clamping and automatic tool changing. Windows

based PC controller with full 5-axis simultaneous control,

network and remote diagnostics capability with 5-axis

program teaching pendant are standard features.

A new heavy structure design and improved CNC

control software gives the Hendrick 20ZXG CNC 3-

axis router high

speed and accurate

machining capabilities.

Feed rates up

to 2,500 inches per

minute and positioning

accuracy of

+/- 0.002 inches

with repetitive

accuracy of +/-

0.008 inches are

obtained. The moving

gantry design

utilizes AC servo drives, linear ways and ball screws

on all axes for smooth and accurate movement. Up

to 15 hp, high frequency router spindles with automatic

tool changing capability are available. Other

features include a PC controller with built in

CAD/CAM software, a vacuum table machined for

zoning and pod fixturing, a low vacuum pressure

safety cut off and air blast tool cooling. The machine

is available in many different table sizes.

Saws for Cutting Plastics

Hendrick’s economical rail-type saws are available

in models that range from 54” to 150”

length of cut, manual or automatic operation,

standard 6” depth of cut and a host of options for

special applications.

standard 6” depth of cut and a host of options for

special applications.

Their computerized

panel cutting

line includes the

PRO-V, PRO-H,

PRO-AM, Legacy

and Patriot-SRP

models which offer

solutions from

entry-level through

continuous, high

production, full

plant automation.

Space saving vertical

sawing and automatic loading/off loading machines

are available. Each model is designed to cut virtually all

plastic material including phenolics, glass-epoxies,

mechanicals, rod, tubing, etc., from large to very small

parts.

For additional information, contact Dan Wiggin, Hendrick/

RWH Industries, Inc., 32 Commercial Street, Salem,

MA 01970, 978-741-3600, Fax: 978-744-0242, E-mail:

info@hendrickmfg.net, Web: www.hendrickmfg.net.

Thread Inserts For Plastic

E-Z LOK offers an expanded line of diamond knurled

thread inserts which included internal thread sizes

from 0-80 to 3/8-16 and from M3 to M6.

Available in both brass and stainless steel, the

inserts

can be “cold” installed which significantly reduces molding

costs by multiplying shots-per-hour. Plus, reject-waste

caused by misaligned and faulty inserts is minimized and

the need to “chase”

threads is eliminated

inserts

can be “cold” installed which significantly reduces molding

costs by multiplying shots-per-hour. Plus, reject-waste

caused by misaligned and faulty inserts is minimized and

the need to “chase”

threads is eliminated

In addition to providing

clean threads,

the inserts also furnish

screw-locking action

unattainable in molded-

in inserts. A flanged version of the insert is available

for terminal strips and like applications in electronic

assemblies. Free samples are available on request.

For additional information, contact Steve Schaeper, E-Z

LOK, 240 E. Rosecrans Avenue, Gardena, CA 90248,

800-234-5613/310-323-5613, Fax: 310-353-4444, E-mail:

sschaeper@ezlok.com, Web: www.ezlok.com.

Static Eliminator

Ionix Technologies Inc. announced the release of its

newest model Ionix for the plastic fabrication market.

Now cleanup is fast and easy with Ionix’s new

patented

static elimination technology.

patented

static elimination technology.

The new PL300 operates by making air, which is normally

an electrical insulator, an electrical conductor.

Therefore, when Ionix is installed in an air blow off line,

the Ionix-treated air acts as an electrical grounding path

conducting the charges away or to each other.

The PL300 represents the most economical method for

fabricators to blow off debris from plastic. It is especially

useful for

thermoformers

and fabricators cutting,

drilling or

routing

plastic. It

saves labor

for cleanup and leaves no residue which could affect

finishing. Ionix contains no nuclear or hazardous materials.

When the cartridge is exhausted, it can be disposed

of in normal recycled waste.

For additional information, contact Dirk Smith, Ionix

Technologies Inc., P.O. Box 3487, Boca Raton, FL

33427, 800-246-1784/561-241-1147, Fax: 561-241-3116, E-mail: info@ionixtechnologies.com, Web: www.ionixtechnologies.com.

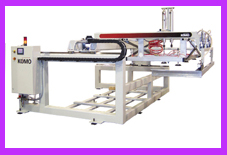

Material Handling

Systems

Komo Machine, Inc., designers and builders of precision

CNC routers, introduced

two Material Handling

Systems, one for the Solution Traveling Gantry CNC

machine and another for the Mach Series of machine.

two Material Handling

Systems, one for the Solution Traveling Gantry CNC

machine and another for the Mach Series of machine.

Komo’s line ranges from material handling tables to a full

blown automatic panel loading system.

The Solution now can be equipped with an

automated part removal system to unload

your machine

faster and

clean the

table in one

process to

allow for

more

machining

time. It is ideal for the small

to medium sized shops.

The fully Automatic Panel Loading System is designed

to be coupled with the Komo Mach Series of machines

and will load, clean the router table and unload your parts

in one continuous cycle that is under 25 seconds.

Constructed in a modular fashion, the system is

designed to be expanded for multiple bunk storage so you

can run a variety of programs and materials. This system

will also increase operator safety and productivity by

keeping them out of the machining envelope and allowing

them to sort and remove parts while the machine is cutting

the next nest.

Software

Komo also introduced the next version of its CAD/CAM

software, Router-CIM 2006 which is fully compatible

with AutoCAD® 2006.

Stay Down Nesting has

been introduced in the new

software. The true shape

nesting engine has been

enhanced with new technology.

Tool stay down

“bridges” shapes together

to create a continuous tool

path. The result is considerably

faster cycle times for

many materials. This feature

eliminates the excess

movement of lifting the

head to move to the next

coordinate and eliminates the need for excess lead-ins;

extending tool life and increasing productivity.

Following the same lines is the common line nesting

option. With this technology, the program can align rectangular

parts and create common line tool path to separate

the parts. Instead of cutting around each rectangle,

two common edges are cut with a single path. This greatly

reduces cycle times on rectangular parts.

Also, verify your program with the Tool Path Verification

option. This allows you to test your NC Code graphically

to insure that the program is exactly as you want it.

For additional information, contact Jeff Erickson,

Komo Machine, Inc., 11 Industrial Blvd., Sauk Rapids,

MN 56379, 800-252-0580/320-252-9887, Fax:

320-656-2471, E-mail: jerickson@komo.com, Web:

www.komo.com.

Routing Technologies

C.R. Onsrud Inc. showcased routing

technologies vital to plastics machining

at the recent AWFS® Fair including

the highly acclaimed C.R. Onsrud

Dual Process Five Axis CNC Router.

This machine features twin tables, twin

five-axis spindles and, with C.R. Onsrud

Dual-process Technology, it has the

ability to run two completely different

five-axis trimming or mouldmaking

jobs simultaneously.

This machine features twin tables, twin

five-axis spindles and, with C.R. Onsrud

Dual-process Technology, it has the

ability to run two completely different

five-axis trimming or mouldmaking

jobs simultaneously.

The Inverted Router has become standard equipment in

acrylics fabrication shops, and C.R. Onsrud demonstrated

the entire three-machine range.

Their website features video demos, machine specifications,

24 hour parts and service and user testimonials.

For additional information, contact

Tom Flowers, John

Akin or Andy Turner,

C.R. Onsrud, Inc., P.O.

Box 419, Highway 21

South, Troutman, NC

28166, 800- 638-8185/

704-528-4528, Fax: 704-528-6170, E-mail: cronsrud@aol.com, Web: www.cronsrud.com.

Composite Drilling

With the continued demand for cutting tools to

effectively machine composites, Onsrud

Cutter LP has introduced a line of solid carbide 8

facet drills, which consist of 4 cutting edges with 2

facets per cutting edge. Designing these drills in

such a fashion reduces cutting forces and eliminates

delamination when exiting the material. Like the

high-speed steel drills, they are also available in

fractional, letter, number and metric sizes.

effectively machine composites, Onsrud

Cutter LP has introduced a line of solid carbide 8

facet drills, which consist of 4 cutting edges with 2

facets per cutting edge. Designing these drills in

such a fashion reduces cutting forces and eliminates

delamination when exiting the material. Like the

high-speed steel drills, they are also available in

fractional, letter, number and metric sizes.

What is an 8 facet drill? An 8 facet drill consists

of 4 cutting edges with 2 facets per cutting edge.

These facets consist of the lip relief and the lip clearance

angle.

Plastic Drilling

Several years ago, Onsrud Cutter LP

introduced their first offering of HSS

drills to accommodate the needs of

plastic fabricators. These drills were

designed with geometry specific to

plastic drilling and have become

extremely popular. The line has now

been expanded to include a wide variety

of fractional, wire, letter and metric

sizes.

drills to accommodate the needs of

plastic fabricators. These drills were

designed with geometry specific to

plastic drilling and have become

extremely popular. The line has now

been expanded to include a wide variety

of fractional, wire, letter and metric

sizes.

With these drills, there is no wrapping,

no interrupted operation, no surface

marring, cleaner holes and no

cleaning or melting.

For additional information, contact Marybeth Thomas,

Onsrud Cutter, 800 Liberty Drive, Libertyville, IL 60048,

800-234-156/847-362-1560, Fax: 847-362-5028,

Web: www.onsrud.com.

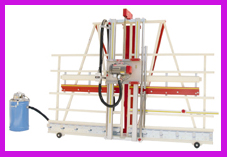

Vertical Panel Saws

Safety Speed Cut manufactures a complete range of

vertical panel saws for processing a wide variety of

panelized materials such as plastic, metal, wood and composites.

Their Model ES52 is well suited for those

demanding high volume production environments with tight tolerance

requirements. The

7400 Series is

perfect for medium

to high volume

applications

where accuracy is

a must.

panelized materials such as plastic, metal, wood and composites.

Their Model ES52 is well suited for those

demanding high volume production environments with tight tolerance

requirements. The

7400 Series is

perfect for medium

to high volume

applications

where accuracy is

a must. The 6000

Series is ideal for medium volume production situations

and their H-Series combines key features from their whole

product line at an opening price point.

Series is ideal for medium volume production situations

and their H-Series combines key features from their whole

product line at an opening price point. With nearly 50

years of experience since first developing their vertical

sawing concept, Safety Speed Cut consistently delivers

accurate, well built panel sizing

equipment that will improve

the efficiency and safety of

your business.

For additional information,

contact Brian

Donahue,

Safety Speed

Cut, 13943

Lincoln Street

N.E., Ham

Lake, MN 55304, 800-772-2327/763-755-1600, Fax:

763-755-6080, Web: www.panelsaw.com.

Air-Vac-Clamp

With a simple flick of the

foot control, the Her-

Saf Air-Vac-Clamp securely

holds plastics,

metals and

nonporous woods from all lateral

movement. The Air-Vac-

Clamp can easily and quickly

secure a large or small workpiece

while allowing full

access to that workpiece. The

Air-Vac-Clamp secures and

releases the workpiece without

leaving a mark.

metals and

nonporous woods from all lateral

movement. The Air-Vac-

Clamp can easily and quickly

secure a large or small workpiece

while allowing full

access to that workpiece. The

Air-Vac-Clamp secures and

releases the workpiece without

leaving a mark.

Safranek Enterprises, Inc.

products include easy-to-use

panel routers, Air-Vac-Clamps, dentil molding machines,

keyholing machines, carbide insert tooling and a shelf

dapper. Each is designed to increase accuracy and precision

while reducing production time.

For additional information, contact Linda Wyant, Safranek

Enterprises Inc., 4005 El Camino Real, Atascadero CA

93422, 800-553-9344, Fax: 805-466-1947, E-mail:

sales@hersaf.com, Web: www.hersaf.com.

Panel Saws

Schelling America, Inc. offers the FLH panel saws which

feature: a saw blade projection of 145 mm (5 3/4”);

a

book/cutting height of 128mm (5”); integration of

Siemens/Fujitsu PC with 17” monitor for optimized ease of

operation; 3 sided wire mesh safety enclosure augmented

by a front protection

curtain with

safety bar and a

quick-action foot

pedal for maximized

operator

safety. Available in

both manual and

automatic loading configurations, the FLH is offered in 3

footprint sizes (FLH 330-10’, FLH 430-12’, FLH 580-16’).

a

book/cutting height of 128mm (5”); integration of

Siemens/Fujitsu PC with 17” monitor for optimized ease of

operation; 3 sided wire mesh safety enclosure augmented

by a front protection

curtain with

safety bar and a

quick-action foot

pedal for maximized

operator

safety. Available in

both manual and

automatic loading configurations, the FLH is offered in 3

footprint sizes (FLH 330-10’, FLH 430-12’, FLH 580-16’).

As with all Schelling panel saws, the FLH can be customized

to meet your individual cutting needs.

For additional information, contact Andreas Schwarz,

Schelling America, Inc., P.O. Box 80367, Raleigh, NC

27623, 919-544-0430, Fax: 919-544-0920, E-mail:

aschwarz@schelling.com, Web: www.schelling.com.

12 Foot Panel Saw

Designed with plastic distributors and fabricators in

mind, the Sigma Impact 105 PLM panel saw from

SCM Group provides superior cutting quality while reducing

material waste and improving yield at an affordable

price.

mind, the Sigma Impact 105 PLM panel saw from

SCM Group provides superior cutting quality while reducing

material waste and improving yield at an affordable

price.

Some of the added value features of the Sigma Impact

105 include a 3.6” cutting capability, high speed carriage

movement with optimized operation for fast cycle times; a

worktable designed to cut thin materials; powerful 18 hp

independent main motor; main

blade cooling; massbalancing

of the

saw carriage to

ensure even

wear and a

perfect edge

finish; triple dust conveying

system and a pusher with clamps for

quick, accurate loading and cutting.

Equipped with a high quality, Windows XP based Dell PC

including CUTTY SHEET optimization software, this saw

guarantees repeatability and easy operator interface. The

SIGMA also includes a modem connection available for

on-line technical support. The Sigma 105 PLM is available

in either 10.5”, 12.5” or 14.5” configurations.

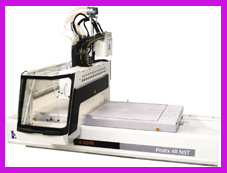

Nested Base CNC Router

SCM Group also offers a full line of CNC routers which

includes the Pratix 48 NST CNC Nested Base CNC

Router for plastics. The router brings total plastic processing

power to an entry-level machine without making

compromises. It features a 4’ x 8’ work area, 9 spindle

drilling head, 10hp HSK F63 router and eight-position

tool changer. The router has a user-friendly interface operated

by a Windows XP platform and a standard office PC

and is supplied with CAD/CAM software. It includes the

industry’s best vacuum table, ideal for

quick changeover and hard-to-hold parts.

Router for plastics. The router brings total plastic processing

power to an entry-level machine without making

compromises. It features a 4’ x 8’ work area, 9 spindle

drilling head, 10hp HSK F63 router and eight-position

tool changer. The router has a user-friendly interface operated

by a Windows XP platform and a standard office PC

and is supplied with CAD/CAM software. It includes the

industry’s best vacuum table, ideal for

quick changeover and hard-to-hold parts.

For additional information, contact

Phil Bryant, SCM Group USA Inc.,

2475 Satellite Blvd., Duluth,

GA 30096, 770-813-8818,

Fax: 770-813-8819,

E-mail: info@

scmgroup-usa.com,

Web: www.scmplastics.com.

Increased Speed

ShopBot Tools Inc., a manufacturer of CNC tools, now

offers the fastest CNC routers in its class. ShopBot’s

PRTalpha line features

advanced,

closed-loop motors

and drivers, giving

the tools a level of

speed and productivity

only seen on

tools five times

more expensive.

advanced,

closed-loop motors

and drivers, giving

the tools a level of

speed and productivity

only seen on

tools five times

more expensive.

The closed-loop,

“alphaStep” motors

and drivers used in

the PRTalpha combine the best features of servo and stepper

motors - offering exceptionally fast and smooth cutting

motions with no “tuning” or “hunting” problems. Cutting

speeds are two to five times faster than current

ShopBots and positioning speeds are up to 1,800 inches

per minute.

ShopBots, manufactured by ShopBot Tools, Inc. of

Durham, N.C., are CNC machines that use basic PC computers

and easy-to-use software to design, cut and shape

wood, plastic or metal products.

For additional information, contact Diane Reynolds,

ShopBot Tools Inc., 3333 B Industrial Drive, Durham,

NC 27704, 800-608-7500/919-680-4800, Fax: 919-

680-4900, E-mail: info@shopbottools.com, Web: www.shopbottools.com.

Multi Grind “O” Flute

Southeast Tool, Inc. is offering a solid carbide 1 flute

spiral, “O” flute with multi grinds for cutting more

rigid plastics like acrylics. The company states that the

benefit of the “O” flute tool is better edge finish by

removing the chips faster. This is especially true on problem

type materials like acrylics. In addition, the “O” flute

design helps in the chip curl to keep the chips from

rewelding to the part that is cut. The tool is currently

available in 1/4” diameter.

rigid plastics like acrylics. The company states that the

benefit of the “O” flute tool is better edge finish by

removing the chips faster. This is especially true on problem

type materials like acrylics. In addition, the “O” flute

design helps in the chip curl to keep the chips from

rewelding to the part that is cut. The tool is currently

available in 1/4” diameter.

Southeast Tool, Inc. also announced that

they have relocated their corporate

headquarters combining their

manufacturing and corporate

offices under one roof.

For additional information, contact

Chuck Hicks, Southeast Tool, Inc.,

P.O. Box 1597, Conover NC 28613,

828-324-2019, Fax: 828-324-4039,

E-mail: router@southeasttool.com,

Web: www.southeasttool.com.

Cutting System

Holzma U.S., a division of Stiles

Machinery, offers the HPP 380 P

cutting system designed expressly for

use by plastic sheet fabricators and

distributors.

Features include solid

construction; servo-powered rack and

pinion drives on the positioning fence

and the saw carriage for quick

response and short cycle times and a

variable speed main saw motor to

optimize cut quality and productivity.

A coolant system on the main saw

blade of the HPP 380 P helps extend

blade life. The HPP 380 P features

Holzma’s unique side pressure device.

Located underneath the table, it

insures that materials are positioned

firmly against the right angle fence

resulting in square cuts. The HPP

380’s compact footprint and availability

in both left and right hand configurations

allow it to fit into many different

floor space situations.

Features include solid

construction; servo-powered rack and

pinion drives on the positioning fence

and the saw carriage for quick

response and short cycle times and a

variable speed main saw motor to

optimize cut quality and productivity.

A coolant system on the main saw

blade of the HPP 380 P helps extend

blade life. The HPP 380 P features

Holzma’s unique side pressure device.

Located underneath the table, it

insures that materials are positioned

firmly against the right angle fence

resulting in square cuts. The HPP

380’s compact footprint and availability

in both left and right hand configurations

allow it to fit into many different

floor space situations.

Ergonomically constructed, the

HPP 380 P reduces operator fatigue

with a comfortable worktable height

and remote starter bar. Contributing

to the HPP 380’s ease of operation

are Holzma’s unique “touch-free”

magnetic measuring system, automatic

cutting height and length,

automatic side pressure device

placement and a program fence

positioning speed of 264 fpm. A 17”

SVGA monitor, Windows NT PCbased

control and modem diagnostics

simplify operator training and

technical support.

For additional information, contact

Bill Pitt, Holzma U.S., 1200 Tulip

Drive, Gastonia, NC 28052, 704-861-8239, Fax: 704-867-4140, E-mail:

bpitt@stilesmachinery.com, Web:

www.stilesmachinery.com.

Nested-Based Machining Center

The Weeke BHP 200 Optimat

machining center, available from

Stiles Machinery Inc., is built for any

size manufacturing operation. It’s

designed for routing, boring and

grooving flat components that have

been nested into full sheets of material.  The BHP 200 Optimat is constructed

on a steel frame providing an

uncompromising solid, vibration-free

platform for the machining head and

the THK linear motion guides ensure

straight line tracking at high travel

rates, with outstanding stability and

performance. The BHP 200 comes

standard with WoodWOP software

and a proven interface to most popular

manufacturing software packages.

The BHP 200 Optimat is constructed

on a steel frame providing an

uncompromising solid, vibration-free

platform for the machining head and

the THK linear motion guides ensure

straight line tracking at high travel

rates, with outstanding stability and

performance. The BHP 200 comes

standard with WoodWOP software

and a proven interface to most popular

manufacturing software packages.

Additional features on the BHP

200 include an 8-fold ride-along tool

changer, 12 hp HSK vertical router

motor, Windows-based Beckhoff CNC

controllers, 8 positioning stops for

single parts as well as full sheets,

high flow vacuum table with multiple

optional configurations,

fiber-optic cables for

communication between the drive

system and the machine control as

well as remote/Web-based diagnostics

and technical support.

For additional information, contact

Steve Waltman, Stiles Machinery Inc.,

3965 44th Street SE, Grand Rapids,

MI 49512, 616-698-7500, E-mail:

swaltman@stilesmachinery.com,

Web: www.stilesmachinery.com.

Two New CNC Routers

Techno, Inc. announced that a new size of CNC router

has been added to the LC Series product offering: the

78120 Model LC Series Machine. The new LC has a work

envelope of 78” x 122” x 5” and is constructed on a heavy

steel base weldment that is stress relieved.

This new

machine, ships complete with closed-loop servo motor

drives as well as Techno’s easy-to-use Windows-based

GCode Interface with free upgrades for the life of the

machine. The new wide-model CNC Router can be

equipped with a variety of spindles and accessories,

including: automatic tool changer, vacuum table/pump,

laser scanner or 4th axis rotary table.

This new

machine, ships complete with closed-loop servo motor

drives as well as Techno’s easy-to-use Windows-based

GCode Interface with free upgrades for the life of the

machine. The new wide-model CNC Router can be

equipped with a variety of spindles and accessories,

including: automatic tool changer, vacuum table/pump,

laser scanner or 4th axis rotary table.

Techno also introduced their Premium Class CNC

Router. This heavy-duty router has a

stress-relieved steel base and

uses top-of-the-line THK rails

and bearings. To

ensure minimal

maintenance and

machine longevity,

all three axes are

equipped with ball

screws as well as

Brushless Servo Motors to provide

power and accuracy when you need it. These quality components

create a standard of optimal performance in each

and every one of your routing applications.

The routers are ideal for the production routing of plastic,

wood, aluminum, composites, either in nested-based

form or individual component processing. Techno provides

their easy-to-use Windows PC-based CNC Interface

for communicating with any CAD/CAM GCODE outputting

system.

Routers are available in 5-standard

sizes ranging from to 60” x

60” to 60” x

192” (with special

sizes available

upon

request). A

complete line

of CNC accessories

that are

fully compatible with the Premium Class Routers (e.g. vacuum

table, automatic tool changers, dust collection, drill

banks, etc.) are also available.

For additional information, contact Roy Valentino,

Techno, Inc., 2101 Jericho Turnpike, New Hyde Park, NY

11042, 800-819-3366, Fax: 516-358-2576, Web:

www.techno-isel.com.

Tooling Catalog

A new 40-page catalog from Vortex Tool Company, Inc.

provides an overview of more than 400 different

types of tools the company

designs and manufactures for

the woodworking and plastics

industries. The catalog includes

easy-to-use selection guides

and detailed technical information

on Vortex’s high-performance

router and insert cutting

tools. The 2004 recipient of the

IWF Challengers Award, Vortex

Tool Company, Inc. produces

tools with cutting edges in various

grades of carbide, stellite, high-speed steel and polycrystalline

diamond, and provides custom tool design,

retipping and sharpening services.

types of tools the company

designs and manufactures for

the woodworking and plastics

industries. The catalog includes

easy-to-use selection guides

and detailed technical information

on Vortex’s high-performance

router and insert cutting

tools. The 2004 recipient of the

IWF Challengers Award, Vortex

Tool Company, Inc. produces

tools with cutting edges in various

grades of carbide, stellite, high-speed steel and polycrystalline

diamond, and provides custom tool design,

retipping and sharpening services.

To request a free copy of their catalog, contact Mike

Serwa, Vortex Tool Company, 5605 Jelinek Avenue,

Schofield, WI 54476, 800-355-7708/715-355-7707,

Fax: 715-355-7353, E-mail: info@vortextool.com, Web:

www.vortextool.com.

|