|

CNC Pressure Beam Saw Increases Accuracy and Productivity

In the winter of 2004, Tom Ryan, President and Coowner

of Hart Supply Company, a full service plastics

distributor and fabricator based in Hingham,

Massachusetts, decided it was time to replace the company’s

out-of-date, antiquated beam saw with a cutting system

that would increase accuracy and provide the edge quality

on acrylic that his customers were demanding.

Hart Supply is a very diverse company, supplying materials

to a variety

of different industries. Display and P.O.P.

manufacturers make up the majority of Hart Supply’s business

but they are also very active in the graphic arts, glass,

sign and building products industries. Hart Supply inventories

a wide variety of materials, all with unique qualities and

different cutting challenges for the saw operator. On an

average day they will cut: acrylic, polycarbonate, aluminum,

PVC, foam, sign board, styrene and a variety of other materials

that range in thickness from .060 to 2”.

of different industries. Display and P.O.P.

manufacturers make up the majority of Hart Supply’s business

but they are also very active in the graphic arts, glass,

sign and building products industries. Hart Supply inventories

a wide variety of materials, all with unique qualities and

different cutting challenges for the saw operator. On an

average day they will cut: acrylic, polycarbonate, aluminum,

PVC, foam, sign board, styrene and a variety of other materials

that range in thickness from .060 to 2”.

Ryan determined that if his company was to grow and

be competitive in the cut-to-size business he had to offer

superior cut quality and shorter lead times. After evaluating

several manufacturers of CNC beam saws, he choose

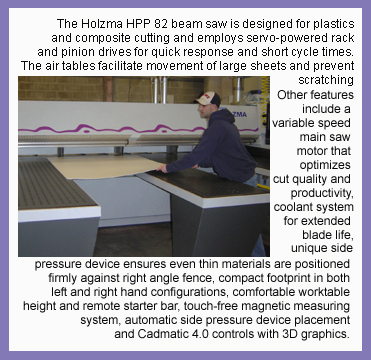

the Holzma HPP 82 for plastics, which incorporates a

number of features designed expressly for the cutting of

plastic sheets.

The variable speed main saw motor on the HPP 82

allows the operator to choose the main saw rim speed

according to each plastic’s cutting properties. This capability,

taken with the mist coolant system on the main saw,

helps achieve maximum cutting speed and optimal edge

finish, boosting both productivity and part quality. A key feature of the control on the HPP 82 is the Material

Parameter Library, which allows automatic selection of

such variables as the rim speed, cutting speed and blade

exposure by material type so the best settings are chosen

automatically every time for consistency of performance

and output.

At the time of purchase, Hart Supply also decided to

invest in the

powerful Cut Rite Production Control and

Panel Optimization software offered by Holzma U.S. Cut

Rite works on a cost basis, comparing both the cost per

hour of machine time and the cost per square foot of

material being cut, to arrive at the least cost solution for

the required parts from the given sheet stock sizes. The

optimized patterns can be generated from internal or

imported parts lists and the resulting patterns downloaded

electronically directly into the Cadmatic control on

the saw, thus eliminating all setup time, the potential for

setup error on the shop floor and typically saving 25-35%

of the production day by eliminating manual setup.

powerful Cut Rite Production Control and

Panel Optimization software offered by Holzma U.S. Cut

Rite works on a cost basis, comparing both the cost per

hour of machine time and the cost per square foot of

material being cut, to arrive at the least cost solution for

the required parts from the given sheet stock sizes. The

optimized patterns can be generated from internal or

imported parts lists and the resulting patterns downloaded

electronically directly into the Cadmatic control on

the saw, thus eliminating all setup time, the potential for

setup error on the shop floor and typically saving 25-35%

of the production day by eliminating manual setup.

The challenge to improve cut-to-size capabilities came

from the sales force, which number nine inside and nine

outside sales reps covering all of New England and

Eastern New York and 14 trucks on the road daily.

Answering the challenge paid off as the cut quality and

capacity of the new saw helped Hart Supply increase cutto-

size volume 5-fold.

Gary Hermanson, Hart Supply’s department manager,

is thrilled with the service and support he is getting from

Stiles Service and Holzma Tech Support. Saw operator,

Mark Bates, said “The HPP 82 with Cadmatic control is

one of the most user-friendly machines I have ever operated.”

“The overall performance of the machine exceeds

our expectations,” said Hermanson. “We look forward to

many more years of precision cutting and reliable use.”

Advantages of a Beam Saw

Electronically controlled, pressure beam equipped

panel saws of the type which Hart Supply purchased offer

a wide variety of advantages to the plastics sheet fabricator.

First, the electronically controlled program fence is

equipped with clamps which link the sheet or stack of

sheets to it, thereby guaranteeing precise positioning and

ensuring tight tolerance component accuracy and squareness.

Second, because the saw utilizes a pressure beam,

this type of cutting equipment can effectively cut one sheet

or many at a time with clean, attractive edge quality

throughout the stack. Third, because the pressure beam

rigidly clamps the sheets prior to cutting, the quality of cut

on this type of saw is far superior to that achieved when the

sheet is physically moved past the cutting blade. Fourth,

because of the capability to stack-cut and the physical

speed of this type of saw, both turnaround times and direct

labor are minimized. Finally, because the saw itself does all

the workpiece positioning and because the stack of sheets

is firmly clamped by the pressure beam during the cutting

process and because the blades on the saw are below the

machine bed except when cutting, this type of cutting

equipment is one of the safest methods for cutting plastic

sheet goods.

For more information, contact Bill Pitt, Holzma U.S.,

1200 Tulip Drive, Gastonia, NC 28052, 704-861-8239,

Fax: 704-867-4140, E-mail: bpitt@stilesmachinery.com,

Web: www.stilesmachinery.com.

|