|

ROUTING: Routing & Trimming PET

PET (polyethylene

terephthalate)

is a popular

material for thermoforming.

PET can be formulated

several ways: x

as unreinforced, glass

fiber reinforced, other

reinforced and as PETG,

to name a few. Each of

these formulated materials

have unique characteristics

which may

require different cutting

tools, spindle speeds,

feed rates and fixturing

to optimize finish and

production rates. Unreinforced PET and PETG are flexible

materials that will flutter when machined if not fixtured

properly. All PET materials can be gummy yet tough and

require the less violent cutting action of an O flute router

bit. Do not use V or Z flute cutting tools with PET because

all grades are subject to crack propagation which will

occur more frequently with such geometry.

PET is used for POP displays, drafting templates, window

well covers, beverage centers, auto accessories and

many types of clear or see through covers. Routing these

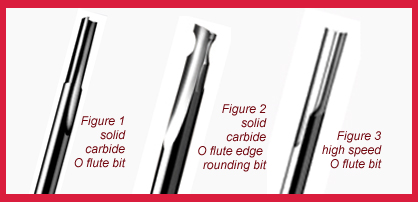

products on a CNC router is best accomplished with

solid carbide single edge O flute router bits, such as the

one shown in Figure 1.

If a curved edge is required,

then a solid carbide

O flute edge rounding

bit as shown in Figure

2 is the best choice.

Both tools are also available

in a two flute configuration

which can be

tested if finish is a

problem with the single

flute tool.

If air routers are

being used to rout or

trim unreinforced PET

or PETG then high

speed steel O flute

router bits may be the most cost-effective choice. The

high speed O flute bit is shown in Figure 3. Solid carbide

O flute bits are also a good choice for air routers when

cutting all types of PET.

When programming a CNC router for cutting PET, there

are a few considerations that will dramatically affect production,

scrap and finish. Entry into the cut should be a

ramping and not plunging action. Outside or perimeter

sharp corners should be programmed as a loop or exit

ramp movement to prevent tool stops or dwells which can

cause crack propagation, heat or burning. Spindle speed

should be set at 18,000 rpm and feed rates between 200

to 350 inches per minute for 1/4” inch and below diameter

tools. PET should be cut as fast as possible with a one

pass cut. There is reasonably little experimenting to be

done other than finding the fastest speed rate when routing

PET materials once the right cutting tool has been

selected and proper programming techniques have been

employed.

For more information, click on the Author Biography at the top of this page.

|