|

ROUTING: Preparing for Plastic Routing Part II

This article is the second of

a two-part series designed

to

help fabricators improve

their machining of plastics.

As companies make the transition

from the routing of

wood or aluminum to the

machining of plastics, there are a

number of preliminary procedures

and considerations that can help

ease the conversion and ensure a

smooth transition.

Periphery factors in the routing of

wood and aluminum can become some

of the most significant aspects of plastics

machining. Good planning and

preparation can help ease these factors

and the costs associated with the

startup of a new machining process.

This article is the second of a twopart

series that discusses the need to

have active preparation when making

the transition from wood routing to

plastic routing. Part 1 discussed the

CNC router and its associated hardware.

Part 2 will discuss tooling and

material selection as well as programming

considerations.

Depending on the customer’s

requirements, fabricators may have

leeway in specifying exactly what

material they will have to rout. This is

an important option and should be

taken advantage of whenever feasible

in order to reduce machining

headaches down the road.

Some plastic sheet manufacturers

produce variations of their common

sheet goods that are marketed as

having improved machining characteristics.

By all means, try these. They

typically produce better chips, do not

melt or scar as much and can sometimes

reduce the problems associated

with chips wrapping on the cutters

during plunging operations.

Various grades of the same type of

sheet can exhibit tremendously different

routing characteristics. UV protectants

can inhibit good chip formation,

fillers can cause premature cutter

wear and different sheet colors

can affect the quality of the edge finish.

Some grades may even be listed

as co-polymers. These co-polymers

may be listed as a single sheet type

but frequently contain a second plastic

in the formulation. It is better to

test cut new grades before estimating

tooling costs and routing times

because of these issues.

Another characteristic to verify

with sheet manufacturers is if the

material exhibits different machinability

going in the extrusion direction

or across it. This can be thought

of as cutting with the grain or crossgrain.

Most plastics do not react differently

in regards to extrusion direction,

but the few that do have caused

some fabricators many headaches.

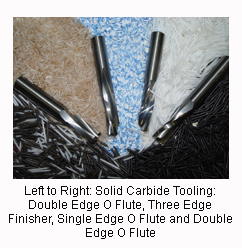

Tooling Selection

Tooling selection should be considered early during the

preparation process. While it will be nearly impossible to

gage tool life (and therefore costs) if it is a new process

and/or material, tooling selection may greatly impact cycle

times, fixturing costs, programming needs and material

waste. Across the major tooling manufacturer’s in the

United States today,

there are more

than 90 styles of

dedicated plastic

tooling with 700 to

800 tools to choose

from. Narrowing

your choices down

to one or two tools

or styles of tools

from a particular

manufacturer can

help you determine

material removal

rates, chip extraction direction and the best diameters for

your applications. This can factor in heavily when later trying

to design fixtures and determine optimum cycle times.

gage tool life (and therefore costs) if it is a new process

and/or material, tooling selection may greatly impact cycle

times, fixturing costs, programming needs and material

waste. Across the major tooling manufacturer’s in the

United States today,

there are more

than 90 styles of

dedicated plastic

tooling with 700 to

800 tools to choose

from. Narrowing

your choices down

to one or two tools

or styles of tools

from a particular

manufacturer can

help you determine

material removal

rates, chip extraction direction and the best diameters for

your applications. This can factor in heavily when later trying

to design fixtures and determine optimum cycle times.

Programming

The very first consideration during programming is cut

direction. For almost every plastic used by fabricators,

conventional cutting will yield a superior edge versus

climb cutting. The exceptions are typically composites or

combined materials. While conventional cutting is very

often the norm in routing (as opposed to climb cutting

during milling), nesting software that seeks to increase

raw material yield and cycle time by reducing the number

of cuts per plastic sheet can force tooling into a climb cut

configuration. If this style of software is used by fabricators,

test cuts should be made to determine whether or

not the climb cut edge finish is acceptable. If it is not, raw

material usage and cycle times need to be re-evaluated.

Another programming consideration is plunging. Many

soft plastics can exhibit severe chip wrap on the cutter

after repeated plunges. Many hard plastics can craze or

“spider web” depending on tool geometry, plunge speeds,

spindle speeds and fixture support.

The most reliable method for solving chip wrap is

ramped cutter entry. This prevents the chips from forming

in a continuous curl and will work 100 percent of the time.

Ramped entry requires special attention to the location of

entry holes and the location of nearby cut paths. Other

methods of solution involve pre-drilling of entry areas and

specially designed router bit point geometries.

Similar to soft plastics, poor plunge finishes on hard

plastics can be solved through a variety of methods.

Ramped entry will once again yield consistent finishes but

is not the only method. Craze-resistant grades of many

popular plastics are available and can withstand the

plunge pressures of standard router bits. Solid fixturing

with support directly underneath the entry point can also

improve the consistency of plunging operations. Special point geometry on cutting tools is typically the last

resort in these types of materials. The best thing to

remember when cutting holes in hard and soft plastics

is that router bits are for making traversing cuts and

drills are for making repetitive holes. The geometry of

drills is far superior to that of router bits for plunging

and they should be used whenever possible.

A final programming consideration should be to

part fixtures. High quality, rigid fixturing methods are

essential to maintaining premium edge finishes and

there are programming methods that can enhance the

adhesion power of various hold-down methods.

A final programming consideration should be to

part fixtures. High quality, rigid fixturing methods are

essential to maintaining premium edge finishes and

there are programming methods that can enhance the

adhesion power of various hold-down methods.

In three-axis routing, a

common method of increasing

holding power is

to leave the paper masking

on sheet goods and to rout

through the plastic, but

not the bottom masking

sheet. This ensures that

the vacuum is not lost and

provides extra vertical and

lateral grip on small

pieces. Routing in this

method requires extremely

flat spoilboards and may

require frequent surfacing of the spoilboards to maintain

their surface dimensions depending on humidity

and temperature variations.

Five-axis routing programs can benefit from higher

spindle speeds that reduce the size of the chips being

formed and consequently can reduce the force being

applied against the fixtures. Multi-flute tools can also be

used to achieve this benefit, but they are susceptible to

increased instances of melt and accelerated cutter wear.

The order of operations in the CNC router program

should also be examined for areas of improvements.

Small cuts and pockets should be made first to utilize

the vacuum area under scrap material. By making

large part cut-outs last, scrap material can be fixtured

the same as finished material and assist in part hold

down. Multiple depth cuts, skin cutting or tabbing can

also be utilized during programming to improve part

hold-down, edge finishes and feed rates.

Advanced planning in the areas discussed in this

article and the last article - Materials, Tooling,

Programming, Runout, Collets, Vacuum, Dust

Collection and Coolant - can help prevent some of the

common missteps that are associated with startups of

new jobs or processes. Addressing these issues can

ensure that the tools, equipment and programs are

ready for use when the job begins and that the run

costs are inline with the estimated costs.

For more information, click on the author biography at the top of this page.

|