|

ROUTING: Real World Routing Solutions

This article is the second in

a four-part series designed to

address common routing problems.

To read Part 1 of this series go to

www.plasticsmag.com and click on

“Routing” under the Series tab.

Cutting tool technology has

evolved dramatically since

the 1980s, when dedicated

router tooling began to take shape.

This, in turn, has enabled primary

and secondary fabricators in the

plastics’ industry to move from

generic tooling to material-specific

cutting tools.

However, there continues to be a lot of confusion

regarding optimal machining methods and practices. In

the last issue, we looked at three real-life applications in

which fabricating problems and their cutting tool solutions

were given. This month, three additional scenarios

are presented.

Scenario 4

Material Cut: ABS and extruded

acrylic

Product: Covers for surveillance cameras

Router Type: 5-axis CNC

Feeds & Speeds: 18,000 rpm at 100

ipm

Initial Tooling: Straight flute generic

plastic tooling

Problem: Initial call was placed

because of consistency problems with

current carbide tipped tools.

This scenario is very typical of what

happens in many manufacturing and

fabrication shops: Tooling users

become comfortable with a particular

tool and do not continue to look for

newly developed or advanced tooling

that can increase production and bottom

line profits. After an on-site visit

with this fabricator and some experimentation,

a new tool was found that

allowed significantly increased feed

rates and, at the same time, exhibited

increased finish quality cutter life.

a new tool was found that

allowed significantly increased feed

rates and, at the same time, exhibited

increased finish quality cutter life.

Using a standard spiral “O” flute

with geometry modified to allow it to

cut both ABS and soft acrylic, the

fabricator was able to increase feed

rates from 100 ipm to 250 ipm

(decreasing part production cycle

times and cost) and was also able to

drop spindle speeds from 18,000

rpm to 16,000 rpm (increasing cutter

life). This was all accomplished

with an improved surface finish on the final part and using

1/4-inch diameter and smaller tooling (Figure 1).

A second problem brought to light in this scenario was

the desire by the fabricator to use a single tooling style

(with various diameters) to handle machining of multiple

types of plastic. Normally, this goes against the trend of

tooling suppliers who are developing

advanced tooling that is very

application-specific. As feed rates

increase and surface finishes

become more and more important,

there will be a significant decrease in the availability

of “generic” plastic tooling.

New tooling is designed for specific applications

and it is extremely difficult to find an optimum cutter

geometry when multiple materials being cut

require different machining parameters. This fabricator

was lucky, but this scenario is going to become

the exception, rather than the rule, as feed rates

and CNC router technology continue to advance.

Scenario 5

Material Cut: Lexan

Product: Fabricated parts for the electrical industry

Router Type: Newly purchased 3-axis router

Feeds & Speeds: 2,500 rpm at 25 ipm

Initial Tooling: Plastic end mill

Problem: The new (and expensive) CNC router was not

paying for itself.

As manufacturers leave the metal-working industry and

move into the primary and secondary plastics fabrication

market, these problems will occur. CNC mills are designed

to machine metals: they are very efficient at it. But 15

years ago or more, their use in the plastics industry began

to skyrocket. They were able to make intricate, multi-axis

cuts on a large variety of soft and hard plastics and were

typically much more efficient and effective than other

methods available for producing complex finished parts.

In those days, CNC routers were not readily available

and those that

existed did not have the multi-axis capabilities

and/or rigidity required for complex parts and

acceptable surface finishes. With current router technology,

feed rates are five to ten times faster than CNC mills

and these feed rates are parameters to be realized, however,

proper tooling must be used.

existed did not have the multi-axis capabilities

and/or rigidity required for complex parts and

acceptable surface finishes. With current router technology,

feed rates are five to ten times faster than CNC mills

and these feed rates are parameters to be realized, however,

proper tooling must be used.

End mills are designed to run at end mill speeds

(up to 8,000 rpm and 50 ipm) and do not complement

a CNC router that is capable of spindle

speeds beginning at 10,000 rpm and approaching

30,000 rpm with 500 ipm feed rates or higher. It

is impossible to justify the cost and return-oninvestment

for a machine in which costs can

exceed several hundred thousand dollars when run

at CNC milling feeds and speeds.

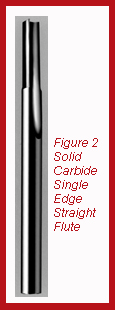

By convincing the fabricator (and the machine operator) that router tooling was designed to perform

best at high spindle speeds and feed rates,

the cutting tool company was able

to show the increased chip extraction

available as well as the subsequent

productivity and the surface

finish improvement (Figure 2).

The end result was the use of a 1/4-inch diameter

dedicated plastic straight “O” flute with speed rates at

150 ipm and spindle speeds at 16,000 rpm. The fabricator

achieved an increase of six time greater throughput

with a better surface finish.

Scenario 6

Material Cut: Acrylic and ABS

Product: Vacuum formed parts of various configurations

Router Type: 3-axis CNC

Feeds & Speeds: 18,000 rpm and 90 ipm

Initial Tooling: 3-wing slotting cutter with arbor

Problem: Part damage and programming concerns

This scenario is similar to the first in that the fabricator

was unaware of new dedicated plastic tooling that

was designed to be an “instant fix” to his problem.

The fabricator was using a slotting cutter designed for

wood to remove flash from a variety

of formed parts. The

geometry of the slotting

cutter, as well as the large

retaining nut at the bottom,

were causing numerous

problems such

as material melting,

scarring and occasional

damage when the programmer

failed to check for

adequate clearance between

the retaining nut and the

material.

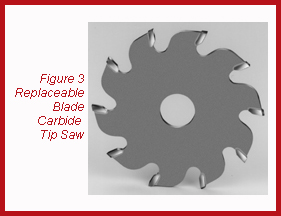

The solution was to use dedicated

plastic saws designed

specifically to run on a CNC router through the use of an

arbor (Figure 3). Tooling such as this is being constantly

designed and marketed to prevent plastics manufacturers

and fabricators from having to “make-do” with tooling that

was designed for another industry or application.

By increasing the tooth count to 10 or 20 teeth (ABS

and acrylic respectively) on a 4 1/2-inch arbor mounted

saw, the fabricator increased feed rates to 150 ipm and

eliminated virtually all post-cutting inspection and

rework operations.

The preceding three scenarios all illustrate two

important facts about router tooling: -

Router tooling is designed for very specific applications

and must be chosen and run accordingly.

- There is continuing advancement in the router tooling

industry - just as there is in the machine industry -

and plastic manufacturers and fabricators must constantly

scan the marketplace for application specific tooling

to solve their problems or increase their productivity.

For more information, click on the author biography at the top of this page.

|