|

New Roto Resins

Aardvark Polymers

announced several

new additions to

their growing line of

Next Generation Roto

Resins. The new offerings

include an FR

nylon with UL94-V0

ratings and the first

commercial Aardalloy

thermoplastic alloy

products.

Aarlon 4055FR is a

premium, flame retardant

type 6/6

polyamide with a

UL94-V0 rating for

flammability. Aarlon 4055FR is formulated without heavy

metals or red phosphorous and is halogen free. Aarlon

4055FR has a high deformation temperature and may be

employed in applications up to 230°C/446°F.

Aarlon 4055FR is a nucleated, heat stabilized, semicrystalline,

type 6/6 nylon with

a unique set of thermal and

mechanical properties. Aarlon

4055FR is applicable in

aggressive chemical and fuel

environments at elevated temperatures.

It is available in

natural and may be dry colored

and printed to suit.

Aarlon 4055FR is vibration,

spin and ultrasonic weldable

and is targeted for applications

in aerospace,

automotive,

public transportation,

electronics, fuel systems and

industrial markets.

automotive,

public transportation,

electronics, fuel systems and

industrial markets.

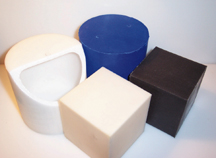

Aardalloy thermoplastic

alloys are generally designed and developed to meet the

demands of a specific application. However, two recent

development formulations offer such broad market

appeal that they are being commercialized for the global

markets.

Aardalloy 3300 is a medium viscosity, high heat,

homopolymer acetal, alloyed with elastomers and modifiers

that significantly increase impact strength and elongation

compared to unfilled acetals. Aardalloy 3300

maintains the high degree of chemical resistance and low

fuel permeation ratios of unfilled acetals. Aardalloy 3300

offers exacting dimensional stability with deformation

temperatures as high as 157°C/315°F.

Aardalloy 3326 is a high viscosity homopolymer acetal

alloyed with greater levels of elastomers and modifiers

that offer the maximum degree of impact strength and

elongation of any acetal product. Aardalloy 3326 is a

thoroughly toughened POM alloy with the same high

degree of chemical resistance and low fuel permeability

found in unfilled acetals. Aardalloy 3326 may be

employed in applications requiring deformation temperatures

up to 100°C/212°F.

Aardalloy 3300 and 3326 may be sterilized with steam

and ETO and may undergo repeated autoclave cycles.

Both formulations may be processed on conventional tooling

and equipment and are weldable, bondable and may

be machined in conventional or CNC processes. Both

materials are offered in natural white and black and may

be printed and dry colored to suit. They are targeted at

applications in fuel systems, automotive, electronics, medical

devices and equipment, construction, chemical containment

and industrial markets.

For more information, contact Michael Gehrig,

Aardvark Polymers, 128 Jackson Street, Lambertville, NJ

08530, 617-803-8682, E-mail: info@aardvarkpolymers.com, Web: www.aardvarkpolymers.com.

|