|

ROUTING: Real World Routing Solutions

This article is the last of our four

part series designed to bring to light

some common routing problems and

the tooling and/or process changes that

became the solutions to the problems.

As more and more CNC

routers are sold for the purpose

of machining plastics,

companies are running into problems

that never existed when they

were hand-finishing or machining

plastics and other materials. The scenarios

here look at four real-world problems that happened

at fabricators in the United States and the solutions

that were found.

Scenario 10

Material Cut: Aluminum skinned acrylic

Product: Large decorative letters for sign displays

Router Type: 3-axis CNC

Feeds & Speeds: 18,000 rpm at 60

ipm

Initial Tooling: 1/4-inch upcut spiral

“O” flute for hard plastics

Problem: Aluminum chips were welding

to the acrylic.

What happened with this fabricator

is a very common problem in the signage

and point-of-purchase industries.

A favorite material used for sign displays

is a clear or colored acrylic covered

on one side with a thin sheet of

aluminum that is attached with glue.

This material is cut out for displays

and letters and a premium finish is

required on both the top (aluminum)

surface and the edges of the material

(the acrylic).

In this particular application, the

material was 3/8-inch-thick acrylic

with a 0.015-inch aluminum skin. The

fabricator was machining the material

with the aluminum side down for better

hold-down and surface finish and

had already selected the correct tool

for the job. The problem was that as

the aluminum and its attached adhesive

were cut and the chips flowed

through the tool’s flute, the chips

would heat up and weld or stick to the

acrylic. This required a hand finishing

operation that the fabricator

was looking to remove from the

process.

This scenario is similar to a situation

written about in the last issue

in which a fabricator was cutting letters

in the same type of material with a 3/16-inch diameter

cutter. In that instance, switching to a tool with better

geometry was able to solve the problem. In this case however,

the glue and aluminum weren’t as well behaved and

the machinist was already using the optimal geometry.

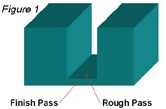

The solution for this problem was to use a modified two pass

system for machining the part.

The aluminum side remained face down. The first pass

of the cutter was set at a depth of 0.030 inch above the

aluminum/acrylic interface and was set to leave the part

0.015 inch oversized.

This enabled

the cutter to remove

the bulk of the

acrylic material without

cutting into the

soft aluminum or the

glue line. The second

pass was machined

at full depth and onsize.

The aluminum side remained face down. The first pass

of the cutter was set at a depth of 0.030 inch above the

aluminum/acrylic interface and was set to leave the part

0.015 inch oversized.

This enabled

the cutter to remove

the bulk of the

acrylic material without

cutting into the

soft aluminum or the

glue line. The second

pass was machined

at full depth and onsize.

This gave a

clean cut to the aluminum and acted as a finish pass to

the acrylic without generating an excessive amount of

heat or leaving a line at the depth step (Figure 1).

Because the finish of the first pass was inconsequential

and the finish pass was removing so little material, the

feed speeds were increased to 250 ipm from 60 ipm and

the total cycle time was less than the original process.

This method eliminated the hand finishing operation,

reduced the cycle time and increased the cutter life. A

win-win situation.

Scenario 11

Material Cut: Cast acrylic

Product: Display cases

Router Type: 3-axis CNC

Feeds & Speeds: 18,000 rpm at 160 ipm

Initial Tooling: 1/4-inch upcut spiral “O” flute for hard

plastics

Problem: Edge finish required multiple polishing operations

after routing

This was a case of too much material for too little tool.

The company was using a 1/4-inch diameter cutter with

optimal geometry for cutting 1/2-inch thick cast acrylic. In

many cases this is a perfectly acceptable method of

achieving a premium edge finish if the equipment

and fixturing is well maintained and very

solid. Unfortunately for this company, time had

taken its toll and the equipment did not have

the rigidity required to remove that depth of

material and still maintain a premium edge finish.

Even with the machine reprogrammed for

a rough and finish pass, the finish did not

improve enough.

The company was using a 1/4-inch diameter cutter with

optimal geometry for cutting 1/2-inch thick cast acrylic. In

many cases this is a perfectly acceptable method of

achieving a premium edge finish if the equipment

and fixturing is well maintained and very

solid. Unfortunately for this company, time had

taken its toll and the equipment did not have

the rigidity required to remove that depth of

material and still maintain a premium edge finish.

Even with the machine reprogrammed for

a rough and finish pass, the finish did not

improve enough.

The second attempt to solve this problem

was to use a multi-fluted acrylic finishing tool.

In many instances, adding flutes can lead to an

increase in surface finish, but it can be at the

expense of heat buildup and tool life. The 3-

flute finisher was used as a finish pass tool

after the single flute spiral removed the bulk of

the material. Unfortunately, this still did not

produce the desired edge quality.

The final solution was to use a 1/2-inch diameter

acrylic finishing tool and to take a single pass (Figure

2). The added stability of the 1/2-inch diameter combined

with the increased surface speed of the cutter edges produced

the premium edge the company was looking for. By

changing their fixturing and programming, the company

eliminated two of the polishing operations.

Scenario 12

Material Cut: Thermoformed acrylic

Product: Display rack

Router Type: 3 1/4 hp hand router

Feeds & Speeds: 18,000 rpm and hand fed

Initial Tooling: 3/16” single edge “O” flute for

plastics (Figure 3)

Problems: Edge finishes were inconsistent

The 3/16” diameter

tool being used by hand

was producing varying finishes depending on

the operator running the material. Depending

on the force and feed rate applied by the operator,

the bits were either breaking, clouding

the edge, or cratering the material. The solution

was to replace the 18,000 rpm router with

a smaller laminate trim router running at

28,000 rpm. The increased surface footage

allowed the cutter to feed more easily and the

edge finishes were produced with a much more consistent

result.

tool being used by hand

was producing varying finishes depending on

the operator running the material. Depending

on the force and feed rate applied by the operator,

the bits were either breaking, clouding

the edge, or cratering the material. The solution

was to replace the 18,000 rpm router with

a smaller laminate trim router running at

28,000 rpm. The increased surface footage

allowed the cutter to feed more easily and the

edge finishes were produced with a much more consistent

result.

Scenario 13

Material Cut: ABS and acrylic

Product: Awards

Router Type: 3-axis CNC

Feeds & Speeds: Variable

Initial Tooling: 1/8-inch diameter spiral “O” flute

Problem: Tools were breaking when materials were

switched

In many cases, router operators feel comfortable with a

particular tool and do not want to be bothered with a

setup change or the expense of testing and operating multiple

tools. This case was no exception. The operator was

very happy with the finish that was generated by the 1/8-

inch spiral “O” flute in both 3/8-inch

thick acrylic and 1/16-inch thick ABS

(Figure 4). Unfortunately,

the tools kept

breaking when they were used to

machine the thin ABS.

the tools kept

breaking when they were used to

machine the thin ABS.

The problem originated from the fact

that the cutting edge length (1/2 inch)

required for the acrylic was too long for

the ABS. By using the same type 1/8

inch diameter spiral “O” flute tool with a

1/4 inch cutting edge length, the breakage

problems were eliminated (Figure 5).

The operator was

able to use the same

tool for both jobs by taking multiple

passes (at higher feed rates) on the

thicker acrylic material without going

through the multiple setups.

able to use the same

tool for both jobs by taking multiple

passes (at higher feed rates) on the

thicker acrylic material without going

through the multiple setups.

This article is the last in a series

describing actual routing problems and the tooling, fixturing

and programming methods used to solve them. The

points that should be taken from these articles are:

Pick the Right Tool for the Job: The single most avoidable

mistake that users of CNC routers make is picking the

wrong tool. There are hundreds of tools available for cutting

hundreds of different types of plastics. Diameter,

geometry, chip evacuation and flute count are all variables

that need to be considered for each machining job.

Employ Solid Fixturing: It is difficult to achieve premium

edge finishes (measured in millionths of an inch) if the

fixturing allows the parts to move a few thousandths of an

inch. This is a critical issue and should be evaluated for

each job setup.

Be Willing to Change Programs: If the finished part

parameters are not acceptable or optimal after selecting

the correct tool and fixture, the answer can frequently be

achieved through programming. Whether it is a rough/finish

pass combination, multiple depths of cut, conventional

or climb cutting, or changes in feeds and speeds, there

are many options available to increase part quality and

throughput.

If these three issues are evaluated and solved, productivity,

quality and efficiency should be greatly improved.

For more information, click on the author biography at the top of this page.

|