|

Polypropylene Welding Lessons Learned

During the past decade I have been asked to visit

many jobsites, project sites, manufacturing plants,

fabrication facilities and have taught many students

the fine art of Polypropylene welding. The most

unique site was this past fall when I went to Kuwait.

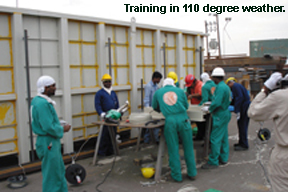

To set the stage, the week before I went to Kuwait I had

just spent 8 days on “North Slope” of Alaska, where it did

get above 32° Fahrenheit. I went back to Florida, packed

my bag for an extended stay in Kuwait where it only drops

below the mid 90s at night.

The project involved fabricating and installing 15 mm

PP liners into steel framed and lined tanks. Each tank was

approx. 39 feet long, 6’ wide and 8.5’ tall. The owner was

able to get PP sheet extruded into 40’ long and 9’ wide

sheets which saved a considerable amount of welding

time. It also presented me with many unique opportunities

to use some creative wisdom and design when it came to

material handling.

PP has a coefficient of expansion equal to 1.8 mm/10°

temperature change per linear meter of sheet stock. All of our

work was done outdoors and every

measurement was corrected back

to an “installed in use temperature”

of approx 20° C. When we arrived

at the project site, the morning

ambient temperature was approx

10-15° C. The sheet temperature,

depending upon it’s location of

standing vertical or still in the material

stack, was always in need of

adjustment based on the actual

material temperature, the future in

use temperature and the ambient

temperature.

For

example,

if the

actual

sheet

temperature

was 13°, the in use temperature was 20° and the cut line

was then adjusted based on the above-mentioned formula.This presented a slight problem until we had everyone trained

to make these adjustments, and then it was checked prior to

cutting. The meticulousness of the workers I had on this project

was beyond my greatest expectations. They would do the

measuring and the calculations in pairs, and would constantly

consult back with me to see if they were correct.

The sheets, being almost 40 feet in length and 9 feet wide,

required a very large lifting beam with 5 cables holding steel

sheet lifting “dogs” or clamps. Another factor of difficulty was

that the winds were usually 15-25

mph coming from a variety of directions

throughout the day.We had at

our disposal a very large crane with

approximately 75’ of boom, which

made it possible to take the sheet

from the stack, to the vertical panel

saw and then into the tanks without

moving the crane. Four guide ropes

were used to control the sheet.

The sheets, being almost 40 feet in length and 9 feet wide,

required a very large lifting beam with 5 cables holding steel

sheet lifting “dogs” or clamps. Another factor of difficulty was

that the winds were usually 15-25

mph coming from a variety of directions

throughout the day.We had at

our disposal a very large crane with

approximately 75’ of boom, which

made it possible to take the sheet

from the stack, to the vertical panel

saw and then into the tanks without

moving the crane. Four guide ropes

were used to control the sheet.

Cutting these large sheets both

vertically and horizontally was

accomplished by utilizing a modified

panel saw. We mounted a panel

saw on the side of two tanks,

installed a set of lower guides

made out of steel channel, installed

vertical guides at every 6’ along the

80’ of saw runners and used the

crane with the lifting beam to move

the PP sheet through the saw. As

the sheet moved through the saw

we were constantly changing the

cables and lifting “dogs” to make

the horizontal cuts.

Once the cuts were made, the sheet was laid down and

the edges to be welded were chamfered, utilizing a hand

held router. The sheets were then installed, flat sheet on the

bottom, two long sides and then the two ends. To hold the

sheets in place, four steel cages were installed inside the

tank to keep the sheets vertical. Spacers were installed

between the steel tank wall and the PP sheet to compensate

for the expansion which the tank PP liner would experience

when the tank would be at its operating temperature.

During the morning hours, many large spacers were used

but as the day progressed, the temperature increased, thus

some of the spacers had to be removed. Working in extreme

temperature fluctuations, expansion and contraction compensation

was paramount to having a successful project.

Next came the welding. The PP panels were not always

installed in the same day or the same time of the day and

had to be given time to stabilize in temperature prior to

dong any welding. We would install the bottom, one end

and one side panel, we would tack weld them into place,

and run a 4 mm hot gas bead along the bottom and the

end. We would then check our tanks for leaks utilizing a

spark tester. We would then install the other side, adjusting

our spacers to compensate for the temperature

changes, and then the other end, doing the same tack

welding and 4 mm root pass and spark test.

In Kuwait, the average humidity at this time was around

20%, and whole country is sand. Sand was everywhere,

including in the tanks, obviously not by design. We were constantly

using vacuum cleaners to remove the sand as it accumulated

inside our work areas.My welding crew consisted of

a “broom man,” a “vacuum man,” a “scraper man,” a “welding

rod cleaner man” and the Welder. Once the sides, ends

and bottom were tacked in place, we could extrusion weld.

With afternoon temperatures somewhere between 25 and

45 degrees C, it would be assumed that we should be able

to run our 20 mm filet welds in a single pass without getting

any voids due to weld temperature cooling/weld shrinkage.

This was not the case. Now some skeptics will say that the

experienced weld voids (pin holes), plastic worm holes or

whatever, were caused by poor quality welding rod, moisture,

not using the correct extruder, not using the correct welder

technique, not using the correct welder shoe, etc. That was

not the case at all. Just to elaborate a little, we used welding

rod that came to us in sealed plastic bags, less than two

months old and stored in a very dry conex container.

We

used three different extruders (manufacturers), and there is

no humidity in Kuwait, and to be sure, I myself welded some.

We

used three different extruders (manufacturers), and there is

no humidity in Kuwait, and to be sure, I myself welded some.

The results were the same. The

solution was very simple, protect

the weld. We put a piece of foil

backed insulation on the weld as

soon as the weld was made and

the voids disappeared.

This is one of those projects

that appeared very straightforward

when based on the drawings

and specifications. But in

actuality, it required the utilization

of all the basics that we

were taught when it comes to welding PP in the field.

Measuring and adjusting for temperatures, cleanliness,

proper equipment utilization, and most of all “Team Work”

is what resulted in success.

I keep waiting for the invitation to come to a project site

to see how well a project has gone, and how perfect all the

welds are.

Written by Larry Rowold, owner and chief instructor of

“The Plastic Welding School,” with its teaching facility

located at 5119 SE 102nd Place, Belleview, FL 32440.

Larry is available for on-site training, classroom training,

project consultation, equipment consultation, etc.

Larry can best be reached on his cell phone 630-319-3480 or email Larry@RREWorld.com. The website for the

school is www.plasticweldingschool.org.

|