|

More Security Against Contamination During Food Processing

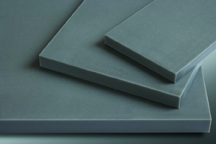

TECAFORM AH ID

(POM-C) is the first

stock shape thermoplastic

that can be

easily and quickly

detected if equipment

failure causes

pieces of material to

mix with the food

product during the production run. The new plastic contains

an additive that enables it to be more readily detected

in the event of an equipment failure. TECAFORM AH ID

can be detected using standard metal detection equipment

during routine quality inspection procedures. Prior

to the introduction of the material, only highly visible, or

specially colored materials would typically be used in production.

However, even these parts are not always noticeable

once the product has been contaminated. This often

makes large quantities of the finished product unusable,

causing significant downtime and potential financial loss.

This new grey acetal is easily and quickly detected by

metal detectors enabling prompt quality assurance and

minimizing potentially costly quarantines and recalls. The

material is FDA and other agency compliant. Its resistance

to chemicals and cleaning agents make it ideal for use in

the production of meat patties, sausages, and other

formed foods, fruit juices, pasta, and pastries, as well as

applications in food and pharmaceutical packaging. In

addition to being easily detected, it features all of the

technical properties needed to produce high quality plastic

components for food processing and other machinery.

The product is being used in housing parts, agitators,

kneading elements and wiper blades for the food industry.

For more information, contact Bruce Dickinson,

Ensinger, Inc., 365 Meadowlands Blvd., Washington, PA

15301, 800-243-3221/856-227-0500, Fax: 724-746-9209, E-mail: bdickinson@ensinger-ind.com, Web:

www.ensinger-online.com.

|