|

High Performance Plastics

High Performance Plastics offer plastic shapes fabricators

materials that have higher strength, higher service

temperatures, and in some cases, resistance to hot

water and steam or chemicals and possess good electrical

properties. Applications can be found in a wide

range of industries including where parts come in contact

with aggressive materials, lining of tanks, pumps,

flanges, fittings, parts in centrifuges and control engineering

industry. Also characterized by a higher cost,

the range of applications that these tough materials

serve demands these high performance physical properties

and justifies their cost. The following section

provides an overview of some exciting new materials,

as well as some that are time-tested, from leading

international manufacturers and suppliers.

Engineering Stock Shapes

Engineering Stock Shapes

Advanced Polymer Technologies (APT) manufactures high

quality extruded stock shapes with minimal stress and

production flexibility from a wide range of engineering

resins. Their ISO based quality system has enabled APT to

service the most demanding applications including medical

devices,

semiconductor

production

equipment and

aerospace platforms.

Standard

materials

include: POM,

PEI, PSU, PEEK,

PVDF, PC, PES

and more, with

standard extruded shapes from 0.375” to 6” rod and slab.

APT can offer their customers production flexibility, special

resins, custom slabs (thickness, length, width) to optimize

fabrication yield, a width range from 12” to 25”, custom

grinding and a high level of technical expertise in

process technology and application development.

For additional information, contact Karen Phanthaamat,

Advanced Polymer Technologies, LLC, 510 Gilmore Ave.

Suite C, Stockton, CA 95203, 209-464-2701, Fax: 209- 464-5760, E-mail: kphan@aptllc.net, Web: www.aptllc.com.

Compression Molding

Capabilities

Compression Molding

Capabilities

Ensinger’s compression molded stock and near net shapes

provide engineers and designers with options and flexibility

in a variety of high performance thermoplastics. Not

every application for engineering thermoplastics requires

high volume production runs of standard materials.

Smaller quantities of

high temperature, high

performance compounds

can often be used to

keep production or

development costs

down. Ensinger’s large

diameter press is capable

of molding up to 81”

in diameter in materials

such as TECAPEEK,

glass filled TECAPEEK

and glass filled TECATRON

PPS. This press

allows for a larger diameter

than any other

manufacturer. Ensinger can also mold virgin PTFE and

UHMW shapes over 25” in diameter.

Ensinger offers a variety of products that can be compression

molded. Typical polymers include TECAPEEK

polyetheretherketone and TECATRON polyphenylene sulfide

(PPS). Typical fillers include glass fiber, carbon fiber,

graphite and Teflon®.

Thin Gauge Materials

Ensinger has also expanded its product line to include a

variety of High Performance thin gauge materials.

Manufactured at Ensinger’s

Penn Fibre manufacturing facility,

the new product offerings

include the following:

TECASON

S Polysulfone (PSU) natural

and TECANYL Noryl EN265

(PPO) black are available from

.040” to .125”. Thin gauge

materials from .031” to .25”

can be supplied in TECATRON 30% glass filled PPS black

and TECAMID 12% glass filled nylon black. TECAPET natural

is offered in thin gauge from .031” to .125”. Ensinger

also has an extensive inventory of thin gauge TECAPEEK

(polyetheretherketone) sheet. Thin gauge high performance

thermoplastics are available in sheets, coils/rolls,

strips and punched parts.

TECASON

S Polysulfone (PSU) natural

and TECANYL Noryl EN265

(PPO) black are available from

.040” to .125”. Thin gauge

materials from .031” to .25”

can be supplied in TECATRON 30% glass filled PPS black

and TECAMID 12% glass filled nylon black. TECAPET natural

is offered in thin gauge from .031” to .125”. Ensinger

also has an extensive inventory of thin gauge TECAPEEK

(polyetheretherketone) sheet. Thin gauge high performance

thermoplastics are available in sheets, coils/rolls,

strips and punched parts.

Ensinger maintains an extensive inventory of thin gauge

materials for immediate delivery from stock. The company

specializes in offering a wide variety of engineering thermoplastic

and thermoset materials in thin gauge strip,

sheet, rolls and punched parts for a broad range of industrial

applications. All federal, military, ASTM and AIAG

specifications are met where applicable.

For additional information, contact Bruce Dickinson,

Ensinger, Inc., 365 Meadowlands Blvd., Washington, PA

15301, 800-243-3221/856-227-0500, Fax: 724-746-9209, E-mail: bdickinson@ensinger-ind.com, Web: www.ensinger-online.com.

High Performance Rod & Sheet

GEHR Plastics offers polyvinylidene fluoride (PVDF) sheet

and rod which is ideal for applications including pumps,

rotation disks, valves, fittings, glide tracks, cog wheels and

chemical processing. PVDF shows a higher tensile

strength, pressure resistance and dimensional stability

than the related PTFE, but friction and insulation properties

are lower. PVDF has a high mechanical

strength and toughness at lower temperature and

is self-extinguishing. The temperature ranges from

-22° F to +300° F.

GEHR Plastics offers polyvinylidene fluoride (PVDF) sheet

and rod which is ideal for applications including pumps,

rotation disks, valves, fittings, glide tracks, cog wheels and

chemical processing. PVDF shows a higher tensile

strength, pressure resistance and dimensional stability

than the related PTFE, but friction and insulation properties

are lower. PVDF has a high mechanical

strength and toughness at lower temperature and

is self-extinguishing. The temperature ranges from

-22° F to +300° F.

Characteristics are high tensile strength; FDA

compliance; high mechanical strength; excellent

radiation resistance;

high chemical resistance;

excellent barrier

properties and

low water absorption.

It is the material

of choice for high

purity; good friction

and wear and tear

values fluid handling

and high UV–resistance.

It produces

toxic fumes when burned and cannot be solvent

cemented.

GEHR also offers ethylen-chlortrifluorethylene (ECTFE)

rod in 1/2" to 5" in 4' lengths. E-CTFE exhibits

extraordinary impact strength at temperatures

ranging from -104° F to +302° F. A great part of

the product properties attributes to the very

smooth surface and differentiates HALAR® from

other fluoropolymers. Due to the fact that E-CTFE is

very pure, this material is being used to process

chemicals and ultrapure water for the semiconductor

industry. Also the permeation resistance to oxygen,

carbon dioxide, chlorine gas and hydrochlorid

acid is 10 to 100 times better than PTFE. Its characteristics

are: extremely high impact strength (up

to -105° F) no break on notched or unnotched

IZOD impact test; good insulation properties; very

good weather resistance; high resistance to radiation;

very high chemical resistance and it is self-extinguishing.

It offers very good sliding properties

and is food safe. Applications include: parts which

come in contact with aggressive materials (machinery

building industry), lining of tanks, pumps,

flanges, fittings, parts in centrifuges and control

engineering industry.

For additional information, contact Bill Shields,

GEHR Plastics USA, 24 Creek Circle, Boothwyn, PA

19061, 800-PVC-GEHR/610-497-8941, Fax: 610-497-8901, E-mail: info@gehrplastics.com, Web: www.gehrplastics.com.

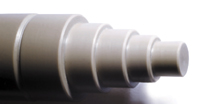

Tubing & Profiles

Hi-Tech Profiles, Inc., a leading manufacturer of extruded

stock shapes has entered into its 22nd year of service to

the plastics distribution industry. Established in 1988, the

company has grown steadily from its initial roots of offering

only Nylon and Acetal stock shapes and now offers virtually

any thermoplastic material including PEEK and

Ultem®. HTP is operating from its brand new facility in

Ashaway, Rhode

Island along with its

two sister companies,

HTP-Meds LLC,

and Hi-Tech Molds.

The three companies

combined offer concept

to part service

with extremely fast

turn around times.

HTP specializes in

the extrusion of all

engineered thermoplastic

materials in

sizes ranging from 0.050” to 2.5” OD. The company offers

an extensive line of tubing, hollow rod and bushing stock

in Nylon and Acetal that is in stock and available for immediate

shipment. Custom sizes are quoted upon request

with over twenty different materials to choose from including

ECTFE, Polycarbonate, PVDF and Polysulfone. Custom

cutting and printing are available upon request with standard

stock sizes available. Co-extruded tubing with two

and three layer construction in sizes ranging up to 1” OD

is also available. Please call for a quote on your next coextrusion

project.

For additional information, contact Brian McGregor, Hi-

Tech Profiles, Inc. 15 Gray Lane, Ashaway, RI 02804, 800-342-5495, Fax: 401-377-2423, E-mail: info@hitechprofiles.com, Web: www.hitechprofiles.com.

Films, Tapes, Fabrics & Belting

Films, Tapes, Fabrics & Belting

CS Hyde Company is the

ideal source for High

Performance Plastic

Products such as films,

tapes, coated fabrics and

belting. CS Hyde brand

names include Teflon®,

Kapton®, 3M™, UHMW,

PVDF, Mylar®, PEEK,

Ultem®, FEP and cast

acrylic.

CS Hyde Company specializes

in converting services:

die-cutting, high-speed sheeting, adhesive lamination.

Plastic Distributors receive special discounts.

Minimums for custom jobs are small, costs are reasonable

and turn-around is quick. Technical assistance is available

for your custom job.

Examples of converting capability: They can laminate

adhesives to many unusual substrates like PEEK, Delrin®,

specialty silicones, Kynar®, Ultem®, thick PTFE and coated

fabrics. They welcome customer-supplied materials to laminate.

They can high-speed sheet custom sizes like 12” x

12”, 12’ x 24”, 24” x 24”, etc. Die-Cut Jobs are priced

competitively. They accommodate small prototype jobs as

well as large quantity orders.

Stock Products are sold by the foot, sheet and roll with

no minimums and same day shipping.

For additional information, contact Tiffany Hoerle, CS

Hyde Company, 1351 N. Milwaukee

Ave., Lake Villa, IL 60046, 847-395-0325, Fax: 847-395-0334,

E-mail: sales@cshyde.com, Web: www.cshyde.com.

Antimicrobial Sheet

Antimicrobial Sheet

King Plastic now offers King Micro-Shield™ in many of its polymer

sheets. King MicroShield is a new

kind of antimicrobial protection that

helps products stay cleaner between

cleanings and inhibits the growth of

product-damaging microorganisms,

including bacteria, algae and fungi

on the surface.

King MicroShield is available in

King StarBoard®, King StarBoard®

ST, King ColorCore®, King Color -Board®, King Hy-Pact® VH, King

PlastiBal® restroom partitions and the

company’s general line of HDPE, LDPE

and polypropylene sheet. Polymers

made with King MicroShield are easy

to clean, disinfect and keep hygienic

using industry standard cleaning procedures.

Constant use of cleaning

solutions will not affect the antimicrobial

protection of the material.

The product is safe, non-toxic and non-hazardous to ship and handle. Microbe

cell walls that come in contact with King MicroShield are destroyed on contact

without creating opportunities for adaptive or resistant strains to form. The

material is non-leaching, with the antimicrobial agent bonded at the atomic

level and integrated throughout the sheet.

If used to build cabinets, case goods or other architectural products, certain

King products that include King MicroShield may qualify for LEED Purple

Building Rating System Points.

For additional information, contact Lou Stegner, King Plastic Corporation,

1100 N. Toledo Blade Blvd., North Port, Florida 34288, 941-493-5502, Fax:

941-497-3274, E-mail: sales@kingplastic.com, Web: www.kingplastic.com.

PVDF Stock Tubing

Petro Extrusion Technologies (PET) manufactures

HYLAR™ PVDF tubing available from stock in eleven

sizes. HYLAR thermoplastic fluoropolymer is strong

and tough as exhibited by its tensile and impact

strength. Compared to many thermoplastics, HYLAR

has excellent resistance to creep and fatigue. It is

non-toxic, tasteless and odorless. It is the engineering

grade thermoplastics material of choice for applications

requiring high purity and exceptional corrosion

resistance properties.

PVDF Stock Tubing

Petro Extrusion Technologies (PET) manufactures

HYLAR™ PVDF tubing available from stock in eleven

sizes. HYLAR thermoplastic fluoropolymer is strong

and tough as exhibited by its tensile and impact

strength. Compared to many thermoplastics, HYLAR

has excellent resistance to creep and fatigue. It is

non-toxic, tasteless and odorless. It is the engineering

grade thermoplastics material of choice for applications

requiring high purity and exceptional corrosion

resistance properties.

Stock tubing is extruded from the highest quality Hylar 460 Polyvinylidene

Fluoride resin that is an extremely versatile engineering fluoropolymer with a

unique balance of physical, chemical and electrical properties.

Other stock products available from PET include acrylic profiles in 6 sizes

from stock and NYLA-GLIDE GR™ Profiles – MDS-filled Nylon 6 profiles available

from stock in 17 standard shapes.

For additional information, contact Robert Petrozziello, Petro Extrusion

Technologies, Inc., P. O. Box 99, 490 South Ave., Garwood, NJ 07027, 800-229-3338/908-789-3338, Fax: 908-789-0434, E-mail: rpetro@petroextrusion.com, Web: www.petroextrusion.com.

PTFE Materials

Plastomer Technologies is a reliable and responsive manufacturer of PTFE

materials for use in critical industries. Focused on providing the customer with

products that meet exact specifications, Plastomer offers fast delivery, superior

communication and no surprises. Plastomer Technologies manufactures

Texolon® and Amilon™ brands of PTFE materials and compounds produced to

standard or custom sizes of sheet, rod and cylinders. Plastomer also offers precision fabrication or machining of seals and component parts.

The Amilon family of PTFE-based materials incorporates a wide range of fillers including, but not limited to: glass,

carbon, graphite, moly

and bronze, each formulated

to fit your

specific application.

PTFE Materials

Plastomer Technologies is a reliable and responsive manufacturer of PTFE

materials for use in critical industries. Focused on providing the customer with

products that meet exact specifications, Plastomer offers fast delivery, superior

communication and no surprises. Plastomer Technologies manufactures

Texolon® and Amilon™ brands of PTFE materials and compounds produced to

standard or custom sizes of sheet, rod and cylinders. Plastomer also offers precision fabrication or machining of seals and component parts.

The Amilon family of PTFE-based materials incorporates a wide range of fillers including, but not limited to: glass,

carbon, graphite, moly

and bronze, each formulated

to fit your

specific application.

These high quality

materials can reduce

maintenance needs by

offering excellent abrasion,

temperature and corrosion resistance.

High Purity Texolon PTFE is also available for those who

need material for critically clean applications. This material

is molded, packaged and labeled in a strictly controlled

environment ensuring the products have the highest purity

for demanding applications.

PTFE products are offered in cylinders and rods from 1”

to 60” in diameter as well as skived and molded sheet

ranging from .001” up to 8” thick.

For additional information, contact Amy Davis, Plastomer

Technologies, 10633 W Little York Bldg 3, Suite 300,

Houston, TX 77041, 800-345-4901, E-mail: info@plastomertech.com, Web: www.plastomertech.com.

Modified PEEK

Quantum Polymers announced the availability of extruded

stock shape plastic products made with AvaSpire® resin

from Solvay Advanced Polymers. AvaSpire is a modified

polyetheretherketone (PEEK) resin that has been formulated

to offer improved ductility, mechanical strength and

higher operating temperature relative to PEEK while

retaining most of the key performance

attributes of PEEK at a lower price

point.

Modified PEEK

Quantum Polymers announced the availability of extruded

stock shape plastic products made with AvaSpire® resin

from Solvay Advanced Polymers. AvaSpire is a modified

polyetheretherketone (PEEK) resin that has been formulated

to offer improved ductility, mechanical strength and

higher operating temperature relative to PEEK while

retaining most of the key performance

attributes of PEEK at a lower price

point.

Quantum Polymers is

offering AvaSpire

PEEK extruded

rods and plates.

Rods are available

from 3/8” to 4” diameter:

plates are available from 3/8” to 3” thickness. The

materials work well for applications requiring a balance of

chemical resistance and mechanical strength. Quantum is

offering this material well suited for price sensitive applications

in healthcare, transportation, electronics, chemical

processing and other areas of manufacturing.

AvaSpire® PEEK is U.S. FDA compliant for food and

healthcare products. It also meets

ISO 10993 specifications for medical devices.

Quantum Polymers manufactures and sells high performance

plastic stock shape products and features short

delivery times, custom sizes and low minimum order quantities.

High performance standard material offerings

include PEEK, Ultem® (PEI), PVDF, PPS, Polysulfone,

Radel®, Noryl® and machine grade PC. These materials

are available in unfilled and carbon/glass/teflon fiber reinforced

grades.

In addition, Quantum offers custom formulated

materials for applications that require physical,

mechanical and electrical properties beyond the reach of

standard off-the-shelf plastic products. These materials

have applications in the aerospace, bio-medical, energy,

food processing, pharmaceutical, semiconductor and

transportation industries.

For additional information, contact Ellen Witherspoon,

Quantum Polymers, 211 Executive Drive, Suite 1, Newark,

DE 19702, 866-737-7012/302-737-7012, Fax: 302-737-7035, E-mail: info@quantum-polymers.com, Web: www.quantum-polymers.com.

High Performance Shapes

High Performance Shapes

Röchling manufactures a full range of high performance

plastics featuring its SustaPEEK line of products including:

SustaPEEK (natural and black), SustaPEEK GF 30,

SustaPEEK CF 30, SustaPEEK HT (High Temp) and

SustaPEEK MOD (Bearing Grade). Röchling’s SustaPEEK

products are manufactured

with the

industry’s most

specified and preferred

PEEK resin

from Victrex.

In addition

Röchling excels

with its SustaPEI

(Ultem®) line which

is comprised of SustaPEI (natural and black) and SustaPEI

GF 30. Röchling’s line of high performance plastics also

includes: Sustatron PPS, Susta PVDF, Susta PPO (Noryl

EN 265), Sustason PSU (Polysulfone) and Sustason PPSU

(Radel) available in a full range of sheets and rods.

For additional information, contact Birgit K. Moecks,

Röchling Engineering Plastics, 903 Gastonia Technology

Pkwy., Dallas, NC 28034, 704-922-7814, Fax: 704-922-1835, E-mail: info@roechling-plastics.us, Web: www.roechling-plastics.us.

Stocking Program

Stocking Program

Simona America Inc. is a subsidiary of SIMONA AG, one

of the leading manufacturers and distributors of thermoplastic

finished and semi-finished products, e.g. plastic

sheets as a composite construction. A composite construction

refers to a combination of at least two materials

with different task profiles. Thermoplastic liners for dual

laminates and steel tank lining make operation far more

economical and efficient with regard to service life, maintenance

and repair as well as production outages. The

products SIMONA® PP-C-PK (block copolymer, polypropylene-

backed), SIMONA® E-CTFE-GK (partially fluorinated high-performance material,

glass-fiber-backed) and

SIMONA® PVDF-SK (polyvinylidene

fluoride, polyesterbacked)

have gained a particularly

prominent position in the

liner materials market.

Materials are generally

stocked in thickness ranges 3 and 4mm x 1500 wide and

20 meter rolls. Delivering above-average performance in

a wide range of applications, the liner materials meet the

full range of required specifications including chemical and

permeation resistance. Simona America offers an extensive

range of products tailored to the requirements of liner

and composite engineering, together with considerable

expertise in these fields.

For additional information, contact John Ploskonka,

Simona America Inc., 64 N. Conahan Drive, Hazleton PA

18201, 866-501-2992, Fax: 800-522-4857, E-mail: mail@simona-america.com, Web: www.simona-america.com.

Medical HPPs

Westlake Plastics offers two formulations of PEEK in rod

and sheet for use in medical applications

including spinal cages, fixation

rods, orthopedic implants, ophthal -

mic tools,

surgical

instruments,

dental

and diagnostic devices and other

medical devices.

Medical HPPs

Westlake Plastics offers two formulations of PEEK in rod

and sheet for use in medical applications

including spinal cages, fixation

rods, orthopedic implants, ophthal -

mic tools,

surgical

instruments,

dental

and diagnostic devices and other

medical devices.

MediPEEK-IM is a high performance

semi-crystalline thermoplastic

designed for long-term body contact

as an implantable material. It is USP

ClassVI and compliant to ASTM

F2026. It has excellent sterilizability

and has been extensively tested to

ISO-10993 requirements.

MediPEEK-T is a high performance

PEEK semi-crystalline thermoplastic

designed for short-term body contact

as an implantable material. It is USP

Class VI and ASTM F2026 compliant.

It has excellent sterilizability and has

been extensively tested to ISO 10993

requirement for short-term implants.

Westlake Plastics offers a wide

range of high performance extruded

and compression molded shapes in -

cluding polyethersulfone, poly phenylsulfone,

polyetherimide and polysulfone.

For additional information, contact Gary King, Westlake

Plastics Company, P.O. Box 127, Lenni, PA 19052, 800-999-1700/610-459-1000, Fax: 610-459-1084, E-mail:

gary@westlakeplastics.com, Web: www.westlakeplastics.com.

| High Performance Plastics Website Directory

|

Advanced Polymer Technologies. | www.aptllc.com |

| Ensinger, Inc | www.ensinger-online.com |

| GEHR Plastics | www.gehrplastics.com |

| Hi-Tech Profiles, Inc . | www.hitechprofiles.com

|

| CS Hyde Company | www.cshyde.com |

| King Plastic Corporation | www.kingplastic.com |

| Petro Extrusion Technologies, Inc. | www.petroextrusion.com |

Plastomer Technologies | www.plastomertech.com |

| Quantum Polymers | www.quantum-polymers.com |

| Röchling Engineering Plastics | www.roechling-plastics.us |

| Simona America Inc. | www.simona-america.com |

| Westlake Plastics Company. | www.westlakeplastics.com

|

|