|

Saws Spotlight

Panel Saw for Plastics

Panel Saw for Plastics

Mayer Panel Saws

are manufactured

to produce mirror

surface edges and

precision tolerances

in a variety

of plastics so your

customer can buy net

sized parts from you. Mayer’s PS2 offers high output with

4.7” blade projection (optional 7.8” cutting height) and

fast traverse speeds. Premium features for the plastics

industry include: RPM and linear speed motor control; mirror

finish cutting on thick plastics; heavy duty pressure

beam for clean stack cutting; PCD; non-proprietary components;

precision cutting tolerances eliminating secondary

machining and a chromed machine table that eliminates

material scratching.

The Mayer Panel Saws are faster and easier to use than

other machines. The PC control allows for complete integration

into networks and databases and barcoding applications.

For additional information, contact Gerri Yarbrough,

Delmac Machinery Group, 4322 Piedmont Parkway,

Greensboro, NC 27410, 336-854-1211, E-mail: sales@delmac.com, Web: www.delmac.com.

Industrial Class Saw

Hendrick’s

SRP PL Enhanced Industrial Class Series highspeed

computerized panel saw is specifically designed for

the plastics industry. Configured with a solid back table,

solid pusher/gripper combination; this preferred plastics

configuration allows for precision cutting of small parts,

narrow strips, thin material, rod and tubing. The one fixed

and two moveable front tables equipped with air floatation

and solid phenolic surfaces are ergonomically beneficial

to the machine operator while manipulating heavy

materials into

position for the

grippers to pull it

back into position.

Hendrick’s

SRP PL Enhanced Industrial Class Series highspeed

computerized panel saw is specifically designed for

the plastics industry. Configured with a solid back table,

solid pusher/gripper combination; this preferred plastics

configuration allows for precision cutting of small parts,

narrow strips, thin material, rod and tubing. The one fixed

and two moveable front tables equipped with air floatation

and solid phenolic surfaces are ergonomically beneficial

to the machine operator while manipulating heavy

materials into

position for the

grippers to pull it

back into position.

The machine

is equipped with a

variable speed rpm 24 hp

main blade motor and 3

hp scoring motor. Material indexing speeds up to 3,000

inches per minute, spray mist blade coolant system, pneumatic

quick blade change, Windows based PC Controller,

LAN interface, on-board optimization software and diagnostics

point to problems and provide “how-to” solutions

are standard features.

For additional information, contact Whitney Wiggin,

Hendrick, 32-34 Commercial Street, Salem, MA 01970,

978-741-3600, Fax: 978-744-0242, E-mail: info@hendrickmanufacturing.com, Web: www.hendrickmanufacturing.com.

Vertical Panel Saws

Saw Trax

recommends two of its vertical panel saws for

cutting plastic, acrylic or Lexan® sheets. Both have heavy

duty material rollers, stops, tapes, a stand and frame

wheels along with a spinning carriage for easy changes

from cross cutting to rip cutting. The difference is the saw

in the carriage. The 2064 (shown) uses a worm drive saw

with a 7.25" blade and the 3062 uses a sidewinder saw

with a 10" blade. Both saws have motors rated at 15

amps. The difference is the higher torque of the worm

drive will not get bogged down and

the 10" saw blades provide a higher

cut quality.

Vertical Panel Saws

Saw Trax

recommends two of its vertical panel saws for

cutting plastic, acrylic or Lexan® sheets. Both have heavy

duty material rollers, stops, tapes, a stand and frame

wheels along with a spinning carriage for easy changes

from cross cutting to rip cutting. The difference is the saw

in the carriage. The 2064 (shown) uses a worm drive saw

with a 7.25" blade and the 3062 uses a sidewinder saw

with a 10" blade. Both saws have motors rated at 15

amps. The difference is the higher torque of the worm

drive will not get bogged down and

the 10" saw blades provide a higher

cut quality.

Vertical panel saws,

take up much less space

in the shop and handling

sheets is easier since

they are moved vertically

in and around machinery.

For additional information,

contact Michael Della Polla, Saw Trax Mfg. Inc.,

3694 Kennesaw S. Industrial Drive, Suite A, Kennesaw GA

30144, 888-SAW-TRAX/770-974-0021, Fax: 770-975- 1618,

E-mail: info@sawtrax.com, Web: www.sawtrax.com.

High Precision Saw

High Precision Saw

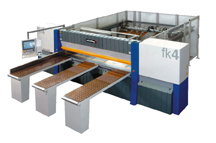

Schelling

announced their new fk4 panel saw designed and

engineered specifically for high speed, precision cutting of

plastic panels. This includes acrylic, PETG, polycarbonate,

polyolefins, PVC, UHMW, phenolics, mechanicals and other

specially engineered materials. The fk4 provides extremely

tight cutting tolerances and chip free cutting of material

as thin as .020" without the use of a protection board. The

machine is also equipped with material recognition software,

a saw blade change database and total panel control

features that provide fast setup times when

changing materials.

Additional features

include; rigid heavy duty construction; stateof-

the-art material handling technology that

automates the loading, cutting and off loading

processes; on-line remote diagnostics for

increased uptime and productivity; saw blade

RPM control combined with blade cooling; online

downloading of optimized cutting patterns and label printing.

For additional information, contact Stephen Bailey, Schelling America, Inc.

P.O. Box 80367, Raleigh, NC 27623, 919-544-0430, Fax: 919-544-0920,

E-mail: sbailey@schelling.com, Web: www.schelling.com.

Built-in Loading Platform

Built-in Loading Platform

A further step has been taken towards

the range renewal of SIGMA Panel Saws.

The new Sigma Impact 107P has a loading

platform, built-in, combining a sturdy

and high performance machine. With a

new shape and framework, the 107P was

carefully designed to ensure vibrations are

absorbed by the ground, thus further improving the cutting quality of the

machine. Ideal for shops looking for flexibility and effective solutions in material

handling, the new saw combines the comfort of a technological machine

with the investment competitiveness.

For additional information, contact Phil Bryant, SCM Group USA Inc., 2475

Satellite Blvd., Duluth, GA 30096, 770-759-3534, Fax: 770-813-8819,

E-mail: pbryantscmgroup-usa.com, Web: www.scmplastics.com.

Optimize Work Flow

Optimize Work Flow

Stiles Machinery Inc. offers cutting solutions

to help plastic fabricators deliver

greater productivity at lower costs.

Designed exclusively for sizing plastic

and component panels, the Holzma

HPP 380P panel saw features a variable

speed main saw motor and automatically

selects the ideal blade rim speed and cutting speed

for each material. The saw carriage is equipped with the unique Holzma side

pressure device that adjusts the pressure according to material type and

achieves beautiful edge quality even with thin PETG.

In addition, utilizing Cut Rite software saves yield, time and money by creating

easy to cut patterns based on your parts requirements and downloading them

directly in the control on the saw, eliminating all set-up time and the potential for

set-up error on the shop floor. As a side benefit, Cut Rite produces a cost per

part and a cost per order: great tools for quoting new business accurately. Cut

Rite will also produce a bar-coded label at the saw while the part is cut.

A national technical support network and same day spare parts program

ensure that no matter where you are located, you can get technical assistance

when you need it.

For additional information, contact Bill Pitt, Stiles Machinery Inc., 3965

44th St. SE, Grand Rapids, MI 49512, 704-861-8239, E-mail: bpitt@stilesmachinery.com, Web: www.stilesmachinery.com.

| Saws Website Directory

|

Delmac Machinery Group. | www.delmac.com |

| Hendrick | www.hendrickmanufacturing.com |

| Saw Trax Mfg. Inc. | www.sawtrax.com |

| Schelling America, Inc.. | www.schelling.com

|

| SCM Group USA Inc | www.scmplastics.com |

| Stiles Machinery Inc | www.stilesmachinery.com |

To learn more about sawing plastics, visit our website and click on Links to Sawing Plastics Archive.

|