|

HDPE Pipe Helps Utah’s Dixie Region

Utah’s Washington

County, in the state’s

Dixie region, is a popular

haven for retirees and

recreational sports fanatics.

Who could blame them? The

beautiful red sandstone landscape,

easy drive to Las

Vegas, and moderate winter

temperatures all work together

to make the region one of

the United States’ fastest

growing communities.

However, a booming population

equates to more demand on water in an area that

receives little to no snowfall and approximately 11 inches

of rainfall per year. With such a premium on water, the

Washington County Water Conservancy District has turned

to high-density polyethylene (HDPE) pipe, for its leak-free

characteristics, durability, strength, flexibility and ease of

installation.

“We have been nothing but successful with HDPE pipe,”

said Chuck Carney, Operations Manager for the

Washington County Water Conservation District. “We’ve

been using it since 1986 and we’ve got it in all sizes from

1-inch to 63-inch.”

“We have been nothing but successful with HDPE pipe,”

said Chuck Carney, Operations Manager for the

Washington County Water Conservation District. “We’ve

been using it since 1986 and we’ve got it in all sizes from

1-inch to 63-inch.”

63-Inch Installation

In the fall of 2009, a new 1,400-foot, 63-inch IPS SDR

17 pipeline was installed, getting more water to a treatment

plant that provides Saint George and the suburban

areas of Washington, Ivins, Hurricane and Santa Clara with

water services.

Two reservoirs provide the water to sustain life in

Washington County – Quail Creek and Sand Hollow. The two

bodies of water are separated by the Virgin River, requiring

any pipelining created between the two reservoirs to be located

under the river bottom.

Previously, a steel

pipeline ran from Sand

Hollow to a hydroelectric

plant. From that plant,

another water line ran

into Quail Creek with a

bypass line tied in just

before the pipes

entrance to Quail Creek.

The bypass line supplies

water to the water treatment

plant that makes it

suitable for the public.

“We chose HDPE

because we had to go

under the river. We

have a 54-inch steel

line that forces us to

sleep with one eye

open,” said Carney. “We

wanted to put HDPE in

and not worry about a

leak or corrosion.”

The goal of the new HDPE

line is to get the water from

Sand Hollow directly to the

water treatment plant without

taking a longer route to the

hydroelectric plant and then

onward to Quail Creek. This

circumvention of the line

allows the water district to

simultaneously perform both

actions; running water from

the hydroelectric plant to

Quail Creek, and running water from Sand Hollow to the

water treatment plant. The ability to get increased water

resources to the water treatment plant is critical as the 40

million gallons-a-day plant looks to double output for the

booming population over coming years.

The installation

of the

pipe required

contractor

Interstate

Rock to divert

the Virgin

River between

the two reservoirs

in order

to lay the pipe

underneath

the riverbed.

After laying

the pipe, the

river was allowed to flow along its natural boundaries once

more. The entire length of pipe was installed with open

trench methods.

The installation

of the

pipe required

contractor

Interstate

Rock to divert

the Virgin

River between

the two reservoirs

in order

to lay the pipe

underneath

the riverbed.

After laying

the pipe, the

river was allowed to flow along its natural boundaries once

more. The entire length of pipe was installed with open

trench methods.

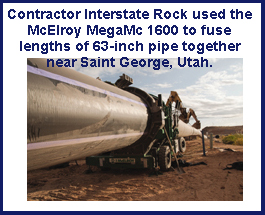

The large sticks of 63-inch-diameter HDPE pipe were

manufactured by PolyPipe and provided by High Country

Fusion, while the MegaMc® 1600 four-jaw fusion machine

used in joining the pipe was provided by ISCO Industries.

Local contractor, Interstate Rock, performed the pipeline

fusion and installation.

Pipe fusion is a widely accepted process that joins two

pieces of thermoplastic pipe together with heat and pressure.

Commonly associated with HDPE, the butt fusion

process starts by “facing” or shaving the pipe ends simultaneously

so that they can be joined together with heat to create

a continuous, sealed pipeline. The welding of the pipes

is accomplished by using a hot plate in contact with the pipe

ends, which heats the plastic to a molten state. Then, after

its removal, the pipe ends are pressed together under a controlled

force to form a weld that is as strong as or stronger

than the pipe itself. Third-party industry research indicates

that HDPE pipe and joints can have a lifespan of more than

100 years.

The McElroy MegaMc 1600 uses 30,000 pounds of

clamping force per jaw and 88,000 pounds of available

fusion force, extremely useful when dealing with such large, heavy pipe.

The drag forces

and characteristics

of this pipe

required

McElroy’s largest

fusion machine

to perform the

operations.

Washington

County has successfully

turned

to HDPE in previous

years.

The McElroy MegaMc 1600 uses 30,000 pounds of

clamping force per jaw and 88,000 pounds of available

fusion force, extremely useful when dealing with such large, heavy pipe.

The drag forces

and characteristics

of this pipe

required

McElroy’s largest

fusion machine

to perform the

operations.

Washington

County has successfully

turned

to HDPE in previous

years.

Three Past HDPE Experiences

While the Washington County Water Conservation

District has had HDPE in use for more than 20 years with

numerous projects, three pipelines really standout in

showing what the pipe can do for a district.

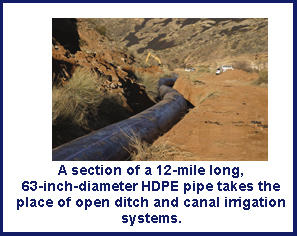

The water district is responsible for irrigation lines to

farmers in the region. The irrigation was originally an

open canal and ditch system that resulted in water losses

due to leakage

and evaporation.

The unreliable

water supply

would cause outages

that were

expensive repairs

and took away

critical water

resources from

farmers when

they needed

them. The HDPE

solution was to

create a 12-mile-long pipeline consisting of 54- and 63-

inch pipe with 16-inch connections for each farmer. By

using the pipeline over the open canal, the district was

able to eliminate the troublesome problem of the canal

“sliding” off the

hillside.

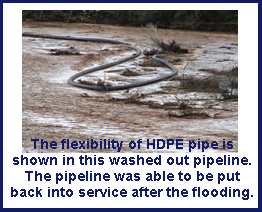

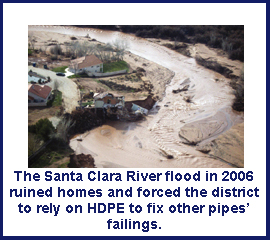

HDPE also

showed its mettle

for Washington

County during a

100-year-flood

event in 2006.

The Santa Clara

River flooded

after heavy snow

and rains, washing

out a 28-inch

HDPE irrigation

line. Carney reports that the HDPE line was never

breached and all the fusion joints were intact, even after

repeated contact with trees, boats, rocks and other flood

debris.

event in 2006.

The Santa Clara

River flooded

after heavy snow

and rains, washing

out a 28-inch

HDPE irrigation

line. Carney reports that the HDPE line was never

breached and all the fusion joints were intact, even after

repeated contact with trees, boats, rocks and other flood

debris.

The worst damage

done to the

28-inch line was

caused by the

contractor,

pulling it from

the river. The

retrieved HDPE

pipe was sorted

out, fused back

together and put

back into service.

“The durability of

the pipe continues

to impress us,” said Carney. “No other type of pipe

could have withstood the battering this pipe received and

remained intact.”

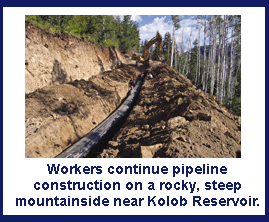

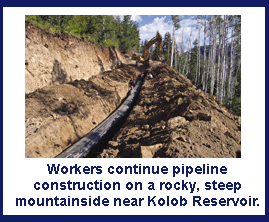

For another water conservation measure, Washington

County took to the mountains to create a 12-mile line of

36-inch HDPE

pipe. The line was

built to ensure

that Kolob

Reservoir would

be full each year

for downstream

irrigators’ use.

The reservoir’s

main water

source was mountain

snow melt,

and the pipeline

stretched from a 9,500’ elevation down to the 8,000’ elevation

height of the reservoir. This design allowed the pipe

to capture the water at the source. By making this water

capture so effective, it guaranteed that the reservoir

would fill every year, even in years with minimal snowfall.

main water

source was mountain

snow melt,

and the pipeline

stretched from a 9,500’ elevation down to the 8,000’ elevation

height of the reservoir. This design allowed the pipe

to capture the water at the source. By making this water

capture so effective, it guaranteed that the reservoir

would fill every year, even in years with minimal snowfall.

The environment for the pipeline was demanding,

requiring the HDPE to traverse rocky terrain with steep

slopes and corrosive soils. Prone to landslides, engineers

chose HDPE for flexibility and strength when soil movement

occurs. Because of the life span of the pipe, workers

won’t have to repair or replace the pipe in areas with no

road access.

Advice

Carney advises municipalities that there is some trade

off when you use HDPE. He believes the confusion

between inner and outer diameters of HDPE compared to

other pipe materials frustrates municipalities that don’t

fully understand all the benefits.

“A lot of communities don’t want to spend more to upsize

to get the same size inner diameter they would with PVC or

ductile iron. I tell them, ‘when you’re up at midnight digging

that up and fixing it, I’m at home sleeping easy.’”

Written by Tyler Henning, McElroy Manufacturing, Inc.,

833 N. Fulton Ave., Tulsa, OK 74115, 918-831-9286,

E-mail: thenning@mcelroy.com, Web: www.mcelroy.com.

|