|

IWF Fair/SPE Preview

The following companies will be exhibiting at IWF

2010, August 25 to 28 and/or the SPE Thermoforming

Conference, September 19 to 22, 2010.

Engraving Set

Amana Tool has recently created an

8-piece set containing the most popular

profiles of its In-Groove™ Insert

Engrav ing System. With In-Groove,

users can customize CNC engraving

machines with a variety of router profiles

– including V-tip, corner round,

bead groove, straight plunge and

core box – on a single tool body. The

8-piece set (AMS-209) includes a tool

body with seven popular profile insert

knives designed for a variety of applications

in laminated materials,

veneers, MDF, plastics, wood and

solid surface. V-tip profiles can also engrave aluminum.

Amana’s entire In-Groove collection contains 30 unique,

industrial-quality knife shape inserts that can quickly and

easily be interchanged while the tool body remains mounted

in the CNC machine, minimizing downtime and helping

maintain consistent cutting accuracy. Industrial-quality

insert knives produce crisp, clean cuts and last at least

twice as long as comparable solid carbide bits.

For additional information, contact Michele Spiegel,

Amana Tool, 120 Carolyn Blvd., Farmingdale, NY 11735,

800-445-0077, Fax: 631-752-1674, E-mail: sales@

amanatool.com, Web: www.amanatool.com.

IWF Booth

6872

Panel Router

AXYZ Automation will introduce the AXYZ PanelRouter, a

CNC machine that is specifically designed to make it easier

to install in many workshops which don't have large

entry ways. The unique upright design and built in material

storage unit, dramatically simplifies material loading,

and allows the user to conveniently store and process 4' x

8' sheets of material.

The PanelRouter is based on the proven AXYZ 4000 and

5000 Series flatbed machines. It shares many of the same components and can be fitted with most of the same

options such as spray mister, knife units, ICS camera registration,

twin heads, popup

pins and many more.

The PanelRouter Series is

driven by the high-powered

motion capability of the

AXYZ A2MC control system.

The A2MC delivers

Seven Segment motion control

and full NC tooling control

to users. Standard features

include choice of 3hp

– 10hp spindles, machine

side sub console for machine operations, vacuum ready aluminum milled bed, vertical

orientation welded steel frame, 6.0”(150 mm) Z-axis

clearance, integrated wheels for easy shop relocation and

linear profile bearings.

For additional information, contact Greg Jenkins, AXYZ

Automation, Inc., 5330 S. Service Road, Burlington, Ontario

L7L 5L1 Canada, 800-361-3408/905-634-4940, Fax:

905-634-4966, E-mail: sales@axyz.com, Web:

www.axyz.com.

IWF Booth 5340

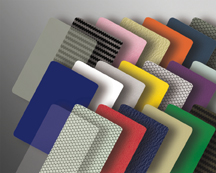

Expanded Thermoforming

Sheet Business

Boltaron is expanding heavy gauge sheet sales into thermoforming

and fabrication markets with new products, a

larger sales force and increased financial backing, following

the May 5, 2010 sale of the company's

thin gauge printstock

business,

announced Lawrence

Schorr, Boltaron CEO

and principal owner.

"The sale was a

strategic move for the

purpose of focusing

Boltaron resources on

its core, growth market

of heavy gauge sheet products for aerospace, mass transit,

industrial, commercial and specialty consumer products

comprised of thermoformed and fabricated parts," says

Schorr.

Boltaron produces high performance, monolithic and

composite PVC/Acrylic, PVC and CPVC sheet products in

50 specialized grades, over half of which carry fire/toxicity

ratings required for aircraft interior components (FAR

25.853 A1 F, Part IV-6565; FAR 25.853 (d); FAR 25.853

A1(i); FAR 25.853 A1, ABD-0031and D6-51377), rail/

mass transit interior components (MVSS, Docket 90,

Docket 90A and ASTM E84), building products (Class 1A),

and industrial/commercial products (FM4910, UL 94V-0,

UL 94 5v, and UL 723).

Sheet products are available in thicknesses from .003 to

3.0 in. (.076 to 76.2 mm) in unlimited colors, textures and

patterns.

For additional information, contact Boltaron Performance

Products, LLC, One General Street, Newcomerstown, OH

43832, 740-498-5900, E-mail: info@boltaron.com, Web:

www.boltaron.com.

SPE Booth 411

Vertical Panel

Saws

Colonial Saw is proud to announce

the latest accessory available for

Swiss-made STRIEBIG Vertical Panel

Saws - touch screen, programmable

stop for increased productivity and

digitally accurate and repeatable

cuts. STRIEBIG Vertical panel saws

cut through a wide range of materials

including melamine, particle

board, MDF, plastic, acrylics, solid

surface materials, ACM (aluminum

composite material) and nonferrous

material. This new option allows the

user to send the stop to a position

entered on the touch screen color

monitor or to a previously saved

dimension. The operator also has

the option to open a cut list at the

saw via the company’s network or a portable USB drive.

This customized, programmable

stop is

manufactured in the

US and available

exclusively through

Colonial Saw.

For additional information,

contact David

Bull, Colonial Saw,

Inc., 122 Pembroke

Street, P.O. Box A, Kingston, MA 02364, 781-585-4364,

Fax: 781-585-9375, E-mail: info @csaw.com, Web: www.csaw.com.

IWF Booth 6252

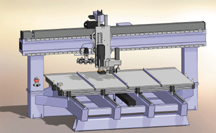

3- and 5-Axis Routers

Diversified Machine Systems (DMS) is an Original Equipment Manufacturer (OEM) of 3- and 5-axis routers and

machining centers – with more than 30 years of innovation

and industry experience building standard and customized

solutions, DMS serves virtually every industry

segment from aerospace and automotive to entertainment

and green energy. DMS CNC routers are routinely used on

materials such as

composites, aluminum,

steel,

plastics, wood and

foams within all

levels of the manufacturing

process.

When quality and

precision matter .

DMS delivers.

DMS now also offers the Freedom Machine Tool (FMT),

Patriot CNC router product line is built around 30 plus

years of CNC router design and manufacturing experience.

Currently they offer 4' x 2',

4' x 4' and 4' x 8', 3-axis,

moving gantry models

in a variety of configurations

that include

spindles up to 11 hp,

automatic tool changing

systems, vacuum

and t-slot tables, and

more. The base machines are nicely equipped with stress

relieved welded steel frameworks, precision ball-screws and profiled rails on all axes, Fagor Industrial CNC controls

and brush-less AC servo motors with matching servo

amplifiers.

For additional information on DMS, contact Ed

Hilligrass, 719-226-5066, E-mail: info@dmscncrouters

.com, Web: www.dmscncrouters.com.

For additional information

on FMT, contact William Oberg, 888-436-8768, E-mail:

sales@freedomcnc.com, Web: www.freedomcnc.com.

IWF Booth 5968/SPE Booth 407

Inserts for Plastics

E-Z LOK has

introduced a new

line of ultrasonic

thread inserts

designed to provide

strong

threads in thermoplastic.

The

brass inserts are engineered for use in tapered holes and

are available in single and double vane designs.

Internal thread sizes range from 2-56 to 3/8-16 and 10-

32 to 3/8-24. E-Z LOK ultrasonic inserts can be installed

with either ultrasonic insertion equipment or a heat driver.

The tapered design reduces installation time and

improves torque and pull out resistance. In addition, the

tapered design applies minimal stress to molded hole

walls.

Ideal for plastic components requiring assembly and disassembly,

ultrasonic inserts are typically used in computer/

instrument cases, terminal boards, electronics and

communications equipment.

For additional information, contact Steve Schaeper, E-Z

LOK, 240 E. Rosecrans Avenue, Gardena, CA 90248,

800-234-5613/310-323-5613, Fax: 310-353-4444,

E-mail: ezlok@ezlok.com, Web: www.ezlok.com.

IWF

Booth 1308

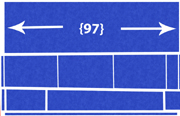

Sheet Sized Parts

Eurosoft, Inc. announced Sheet Sized Parts, a new

add-on option for ARDIS optimization software

that is designed to eliminate

manufacturing hassles

caused by parts as long or

wide as untrimmed raw

boards. Using this option you

can tell ARDIS to ignore trim

requirements for these extra long

or wide parts. This allows them to

be cut on the same raw sheet as parts that have normal trim,

eliminating time consuming manual layout adjustment or saw

programming.

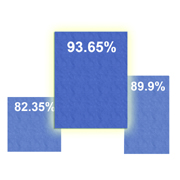

Select Highest Yield

Eurosoft also introduced a new add-on option for ARDIS

optimization software. The Select Highest Yield option is

ideal for manufacturers looking to

reduce or simplify their raw material

inventories. A simple setting in the optimizer

prompts ARDIS to iterate

through all available material

sizes in inventory and select the

single size with the highest yield

for the parts to be cut. This

option is also an excellent estimating tool for inventory

reorder and planning purposes.

For additional information, contact Roman Liedl,

Eurosoft, Inc., 1628 Old Apex Road, Cary, NC 27513, 919-468-3003, Fax: 919-468-3003, E-mail: roman@eurosoftinc.com, Web: www.eurosoftinc.com.

IWF Booth 4723

CNC Router

Hendrick offers the 20ZXGN-ATC-T5 CNC Router featuring

a five-station rack ATC tool changer with a 12 hp high frequency

router spindle. With high speed accurate machining capabilities it is ideal for nested

based manufacturing.

Heavy-duty structure design

and CNC control

software

yields feed

rates up to

2500 inches

per minute

and positioning

accuracy of +/-

0.002 inches with repetitive accuracy of +/- 0.0008 inches.

The moving gantry design utilizes AC servo drives, THK

linear ways and ball screws on all axes for smooth and

accurate movement.

Other features include PC controller with built in

CAD/CAM software, vacuum table machined for zoning

and podfixturing, as well as air blast tool cooling.

For additional information, contact Whitney Wiggin,

Hendrick, 32-34 Commercial Street, Salem, MA 01970,

978-741-3600, Fax: 978-744-0242, E-mail: info@hendrickmanufacturing.com, Web: www.hendrickmanufacturing.

com.

IWF Booth 5752

Antimicrobial Polymers

King MicroShield is a new kind

of anti-microbial, now available

in many of King Plastic’s

sheet products for medical,

laboratory and institutional

applications. It helps products

stay cleaner between cleanings

and inhibits the growth of

product-damaging microorganisms,

including bacteria,

algae and fungi on the surface.

Microbe cell walls that come

into contact with King

MicroShield are physically destroyed on contact, without

creating opportunities for adaptive or resistant strains to

form. It is bonded at the atomic level throughout the

sheet, so it retains its effectiveness for the life of the product

and will not leach out and harm the environment.

King Plastic Corporation has a history of innovation

spanning more than four decades. The North Port,

Florida-based company manufactures dozens of varieties

of polymer sheets, slabs and massive shapes used in a broad range of applications.

These include waterproof cabinetry and casegoods

(commercial and residential), restroom partitions,

pipe-grade and chemical-resistant fabrications, cutting

boards, signage, neutron shielding and, of course, boat

parts.

For additional information, contact Lou Stegner, King

Plastic Corporation, 1100 N. Toledo Blade Blvd., North

Port, Florida 34288, 941-493-5502, Fax: 941-497-3274,

E-mail: sales@kingplastic.com, Web: www.kingplastic.com.

IWF Booth 4456

Thermoforming Machines Line

MAAC Machinery, a market leader in the manufacturing of

sheet-fed thermoforming machines, is releasing several

new features and options to their MAAC and Comet thermoforming

machine lines. New quartz oven technology is

providing for faster cycle times and up to 50% energy savings

when compared to prior technology. More advanced

control systems now allow control of all machine parameters

for quick set ups and precision repeatability. New

quick change utility packages, quick mold change systems

and several advancements in specialty clamping systems

are further allowing for faster set ups, more machine time,

and the ability to produce

products more efficiently

and more cost effectively.

MAAC has also released

new equipment offerings for

the growing composite and

foam based material markets.

In particular, markets

such as automotive, aerospace,

medical and anything where weight reduction, sound

absorption and higher strength are becoming a demand.

These machines are geared toward higher pressure applications

utilizing matched mold processing, and sometimes

using multiple layers of different materials. This new lineup

of machines is geared with faster platens and indexing, highly

sophisticated infrared heating ovens, and typically

automation that will allow decorative coverings to be added.

For additional information, contact Michael Alongi,

MAAC Machinery Corp., 590 Tower Blvd., Carol Stream,

IL 60188, 800-588-MAAC/630-665-1700, Fax: 630-665-7799, E-mail: sales@maacmachinery.com, Web:

www.maacmachinery.com.

SPE Booth 314

Polish Acrylic on a Sliding

Table Saw

The German woodworking machinery company, MARTIN

has develop an option for the MARTIN T74 saw that

would make it possible to finish polishing of acrylic panels

directly after cutting them.

The drive of the sliding table was fine tuned for polishing.

The pressure bar is divided into several clamping areas,

which can be used independently

ensuring gentle and

firm clamping of smaller and

bigger workpieces. A special

fence included in the package

makes it easier to position

the workpieces to be polished.

Even whole stacks of

acrylic plates can be positioned for polishing without difficulty

at the 2 m guide. Acrylic plates as well as whole stacks

of material, with an edge length of up to 3,000 mm and a

thickness of up to 100 mm, can be processed effortlessly.

The package includes the polishing unit, including tool

protection, dust extraction hood and lifting device which

can be lifted and lowered manually. The polishing unit can

only be used with Euracryl ES-100 tools (not included in the

package) polishing a maximum thickness of up to 100 mm.

Planer for Plastics

MARTIN has also developed a planer designed for the processing

of plastics. Specific machine options such as a vacuum

table for the processing of thin material, a zinc-coated dust collection shroud to reduce static and a cutterhead

with an 18° hook angle are designed into the MARTIN

T45 planer. MARTIN also offers its T45 Contour planer

with these options, which allows for the profiling of plastic

material up to 24" wide with a 1" depth of cut.

For additional information, contact Carl Stout, Martin

Woodworking Machines Corp., 8107-M Arrowridge Blvd.,

Charlotte, NC 28273, 704-525-3963, Fax: 704-525-3443, Web: www.martin-usa.com.

IWF Booth 5458

Nested Based CNC

Router

MultiCam announced its new, cost-effective

3000 Series nested based CNC router. The

machine features an all-steel, heavy plate

frame base, 25mm linear bearings and custom

engineered steel castings supporting

the gantry. A wide range of table sizes are

available and an 11 hp automatic tool

change, 100% duty-cycle spindle is standard

along with a 15 spindle, 32mm drill

bank and scoring saw. All 3000 Series

come standard with the MultiCam EZ

Control System featuring an incredibly easy

to use, hand-held operator interface and

fully compatibility with any of the popular

cabinet software packages.

MultiCam Inc. has recently been certified

by Underwriters Laboratories to apply the

UL sticker to all of its electrical enclosures

and controls. This will allow United States based

customers to be in compliance with

all electrical requirements set forth by governmental

or regional electric standards.

With electrical equipment that is identified

with the UL 508 sticker, customers do not

need to hire inspectors before running the

properly installed machine. MultiCam control

panels are also in full compliance with

the NEC and ANSI/NFPA 70 nationally and

with CE/IEC internationally

For additional information, contact John

Harris, MultiCam LP, 1025 West Royal Lane, DFW Airport, TX 75261, 972-929-4070, Fax: 972-929-4071, E-mail: leads@multicam.com, Web: www.multicam.com.

IWF Booth 5412

3-, 4- and 5-axis Routers

C.R. Onsrud, Inc. offers a comprehensive line of high-precision

machining products including 3-, 4- and 5-axis CNC

Routers. Onsrud is well known for superior service capabilities, high-tech training facilities

and an extensive Applications Engineering department

to further reinforce their

pledge to provide the industry

with the best products, service

and customer support.

Now you can get a full-featured

Onsrud 5-axis router

with a 4’ x 8’ table for

$180,000. See them at IWF

as they reveal 3 new models.

For additional information, contact Alyson Onsrud, C.R.

Onsrud Inc., P.O. Box 419, Troutman, NC 28166, 800-638-8185/704-528-4528, Fax: 704-528-6170, E-mail:

sales@cronsrud.com, Web: www.cronsrud.com.

IWF

Booth 5013

High Surface Finishes in

Plastics

Typically, when a ball nose tool is used to machine contours

in plastic, the surface finish is a slightly irregular with

evident tool marks. While this finish is acceptable in most

applications, it is not acceptable in many medical components,

such as a knee

replacement part. A knee

replacement includes an

insert made of mechanical

plastic material. The

plastic insert ensures

smooth rotation between

the metal components of the implant.

The mechanical plastic insert requires a very low Ra

(roughness measurement), which visually is a highly polished

finish. Metal--machined components can achieve a

high polish using abrasives in a secondary operation.

Abrasives cannot be used on plastic, as the abrasives will

roughen the surface of the plastic.

To achieve the surface finish required for the plastic

insert, LMT Onsrud Cutter has developed an innovative solid carbide

ball nose tool that will be available fourth quarter 2010.

The new tool’s unique geometry, specially designed point

and highly polished primary clearance and flute give the

tool the ability to attain a surface finish of 28 Ra in

mechanical plastic. A 28 Ra surface finish is more than

satisfactory for the knee insert.

Other industries that will benefit from the new ball nose

tool include food processing and electronics. In any plastic

application where the surface finish is critical, companies

will want to take advantage of Onsrud’s new ball nose tool.

For additional information, contact Leslie Banduch,

Onsrud Cutter LP, 800 Liberty Drive, Libertyville, IL

60048, 847-362-1560, Web: www.onsrud.com.

IWF

Booth 5658

Evolution of CNC Control

OSAI USA unveils OPENcontrol, a new generation hardware

and software platform for automation and motion

control products connectable to a single network developed

by OSAI and Prima Electronics, hence the name

OPENcontrol (Osai Prima Electronics Numerical Control).

It is a product line consisting of a full range of solutions

addressing the most diverse application requirements:

from OPENBasic, alow priced PLC of compact design, to

the highly sophisticated Numerical Control designed to

handle complete manufacturing processes. The

OPENcontrol product line is intended to stand alongside

and supersede current product expectations, maintaining

the leadership in the wood, glass

and stone markets and at the

same time introducing new applications

worldwide.

For additional

information,

contact

Ivica Simunic,

OSAI USA, 555

W. Algonquin Road, Arlington Heights, IL 60005, 847-952-6580,

E-mail: sales@osai-usa.com, Web: www.osai-usa.com,

www.primaelectronics.com.

IWF Booth 5160

Heavy Duty Panel

Processor

Techno, Inc. CNC Routers offers the Pro Series CNC

Router. Designed to meet the high demands of panel

process manufacturing, the Pro Series is constructed of

large heavy tubing that is both welded and stressrelieved.

Also comprised of precision ball screw drives on

all three axes, THK rails and bearings, high-speed closed

loop servomotor and drives, the Pro Series drive system

ensures minimal maintenance, machine longevity and

superior machine performance.

The series is available in a variety

of standard sizes ranging

from 4’ x 8’

through 6’ x

20’ and can

be customized

upon request.

The machine

can be equipped with a variety of spindle options including

automatic tool changer, collet spindles, drill banks or

multi-spindle setup for high volume part production.

Multiple zone vacuum table, reverse engineering lasers

and 4th axis rotary tables are also available.

Additionally, the New Pro Series’ machine features a

CNC Servo G-Code Interface that is both easy to learn

and operate. This Windows-based interface is a fully comprehensive

CNC program that includes unique highend

features such as toolpath preview with viewing tools and

adjustable screens, built in G-Code editor, machine speed

and spindle rpm override, X/Y axis orientation swapping,

program skip ahead (in case of tool breakage), built in

basic nesting and production logging.

For additional information, contact Roy Valentine,

Techno CNC Router Systems, P.O. Box 5416, New Hyde

Park, NY 11042, 800-819-3366/516-328-3970, Fax:

516-358-2576, E-mail: rvalentine@techno-isel.com,

Web: www.technocnc.com.

IWF Booth 5720

New CNC Router System

Thermwood has introduced a revolutionary new CNC

router system, called the Multi-Purpose 43, for nested

based applications. This new high performance CNC

router is built in the U.S. at Thermwood's Southern

Indiana factory and utilizes a whole new, highly efficient

manufacturing approach which results in a superior structure

coupled with enhanced use of materials, all at a dramatically

lower price.

The new machine features a 61" x 121" fixed table, a 10

hp HSD spindle and an eleven-position automatic tool

changer. It offers high acceleration,

high performance

motions in both

positioning and

cutting. This new

system includes

quality features

seldom, if ever,

found at this price point including full stress relieved weldments,

high-end Siemens drives throughout, THK rails and

three-dimensional volumetric position compensation.

The system also includes Thermwood’s Gen2

SuperControl which sharply distinguishes it from every

other machine and has an impressive list of operating features

all with one purpose, make the machine as foolproof

as possible to reduce errors.

For additional information, contact Jason Susnjara,

Thermwood Corporation, P.O. Box 436, Dale, IN 47523,

800-533-6901/812-937-4476, Fax: 812-937-2956, E-mail:

sales@thermwood.com, Web: www.thermwood.com.

IWF

Booth 5153/SPE Booth 225

Router Tooling

Vortex Tool Company Inc., one of

the industry’s leading producers

of solid carbide and insert routing

tools, has released a new catalog

with over

88 pages

of products.

The

catalog

features

several

new

series of

tools

containing

over

fifty new part numbers. The catalog

also contains valuable technical

information that can be used

to calculate feeds and speeds for

programming CNC machines.

Vortex Tool maintains a huge

inventory with over 10,000 tools

in stock, so most orders will ship

the same day. And as always,

technical support is just a phone

call away.

For additional information, contact

Mike Serwa, Vortex Tool

Company, 5605 Jelinek Avenue,

Schofield, WI 54476, 800-355-7708, Fax: 715-355-7353,

E-mail: mikes@vortextool.com,

Web: www.vortextool.com.

IWF

Booth 7022

|