|

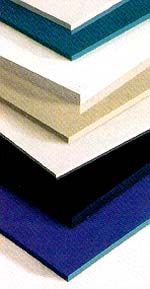

EXTRUDED SHEETING MATERIALS

VERSADUR(r) extruded sheeting materials provide the fabricator with a choice of specialized, high performance sheet materials designed to withstand the hostile operating environments encountered in the chemical, environmental, electronics and food processing industries.

Type I PVC is a self-extinguishing material that provides normal impact grade, acid and alkali chemical resistance for temperatures up to 140ÞF. Applications range from machined and fabricated parts to chemical processing and ventilation equipment.

Type II PVC is a high impact, acid and alkaline resistant material that allows for cold-rolling, vacuum-forming, and ease of fabrication. Applications include ventilation fume scrubbers, ducting, and blower housings.

Homopolymer Polypropylene is an extruded, stress-free, consistently flat, food-grade homopolymer polypropylene sheet with a broad range of chemical resistance to acids, alkalis and some solvents. Applications include plating equipment, wet processing stations, and clean room equipment.

Flame Retardant Polypropylene provides a stress-relieved, smooth-surfaced, lightweight sheet with strong corrosion resistance that meets UL V-O for fire retardancy specifications. The inherently flame-retardant, patented low-density polypropylene composition is suited for semiconductor processing equipment applications. Applications include semiconductor wafer processing equipment, plating and etching tanks, and ventilation equipment.

High Density Polypropylene is an exceptionally strong, stress-relieved, FDA grade extruded sheet with excellent resistance to friction and low temperatures. Applications include equipment designed for prosthetics, wear plates, ventilation and food processing.

For more information, contact Diana Roman; HPG International; 200 Cottontail Lane; Somerset, NJ 08873; 800-344-6080.

|