|

NEW VACUUM WORKHOLDING SYSTEMS

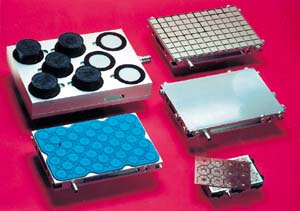

Picture Caption: Shown clockwise, from top left, are the Flip-Pod, Grid-Type, Sintered metal, Slot-Type and Vac-Mat.

IBAG North America introduces an extensive range of Witte vacuum workholding systems.

The Flip-Pod vacuum piece part holding system is ideal for machining plastics. All "pods" self-store, or nest, within the system when not in use. The systems are available in sizes up to 4m2 and can accommodate almost all workpiece configurations.

Grid-type vacuum fixture plates are anodized high-tensile aluminum and provide a sealing effect with an O-shaped elastic seal pressed into the grid slots in a pattern to match the part. They are ideal for heavy milling and can compensate up to .04" unevenness or curvature of the workpiece. Systems range up to 39" x 19.5" x 1.8" (L x W x H), with 1/2" and 1" grid sizes available to suit workpiece requirements.Sintered metal vacuum fixture plates are ideal for extremely thin-walled workpieces and very soft materials. These fixture plates range in size from 5.8" x 3.9" x 1.5" to 39" x 19.5" x 1.8" (L x W x H).

Slot-type vacuum fixture plates are made of extremely light, high-tensile aluminum and are especially suited for light milling and drilling and engraving. Rubber adapter mats permit very fast part changeover and allow the drilling of holes and milling of pockets and cut-outs without vacuum loss. The adapter mat is 0.1" thick to permit tool penetration, reducing secondary operations. Plates are available in sizes up to 39" x 19.5" x 1.8" (L x W x H).

The Vac-Mat&tm; workholding system is a plastic mat, 12" x 8" x .098" thick, with an array of lipped edge workpiece holding "suckers" on the top side, each with a samll vacuum hole through the center. It is ideal for machining parts form plastics and composites. The cutting tool can machine right into and through the inexpensive, disposable mat, eliminating break-out, deburring and other secondary operations. Several mats may be fitted together to acoomodate large workpieces.

IBAG also supplies the ancillary equipment for all these vacuum systems, including modular vacuum units, pumps, tanks, liquid separators, hoses, workstations and maintenance and service kits.

For more information, contact W. Popoli, IBAG North America, 80 Republic Dr., North Haven, CT 06473, 203-407-0397, FAX 203-407-0516.

|