|

ROUTING: Proper Colleting And Maintenance In CNC Routing Of Plastic

Rigidity is a key factor in the routing of plastic

material. The problems associated with rigidity

involve the part, as well as the machine. Parts

must be held solidly with established fixturing techniques,

and the machine must be appropriately maintained to

insure the cutting tool is following the proper tool path in

a rigid and concentric fashion. One of the elements that

aids in this whole process lies in the

area of proper colleting of the router

bit and the ongoing maintenance procedure

associated with router collets.

Types of Collets

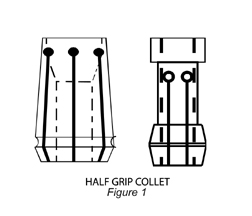

The half grip and full grip collets

are the two basic types found in CNC

routers.

Half grip collets are identified

by slits running from the bottom

or mouth of the collet toward the top

for about 80% of the collet length.

These collets are often counter bored

at the top not allowing the shank of

the tool to

contact the entire length

of the collet. The force holding the tool is primarily generated

at the mouth of the collet, and proves ideal in situations

where the shanks of the router tools are not long

enough to fill the entire collet. (Figure 1)

The half grip and full grip collets

are the two basic types found in CNC

routers.

Half grip collets are identified

by slits running from the bottom

or mouth of the collet toward the top

for about 80% of the collet length.

These collets are often counter bored

at the top not allowing the shank of

the tool to

contact the entire length

of the collet. The force holding the tool is primarily generated

at the mouth of the collet, and proves ideal in situations

where the shanks of the router tools are not long

enough to fill the entire collet. (Figure 1)

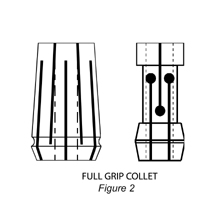

The full grip collet is identified by slits running from

both ends of the collet, which creates specific collet sections.

Full grip type collets allow for squeezing pressure tobe exerted over the entire

length of the collet. (Figure 2)

The full grip collet is identified by slits running from

both ends of the collet, which creates specific collet sections.

Full grip type collets allow for squeezing pressure tobe exerted over the entire

length of the collet. (Figure 2)

Proper Colleting

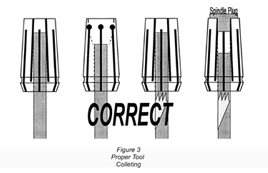

The proper method of colleting

a router bit in the full

grip collet is to fill at least

80% of the depth of the collet.This allows the tool to be

equally distributed on all

sections of the collet and

provides an environment

where the tool runs in a true

circle or concentrically. Without

concentricity, the finish of the plastic part is adversely affected,

and tool failure can occur. There are situations where the 80% rule

cannot be maintained because of inadequate shank lengths or extreme

reach problems.

Consequently, it becomes necessary to fill the void in

the top of the collet with a filler or collet life plug. This is a practical

solution to avoid collapsing of the collet, which may result from not following

the 80% rule. (Figure 3)

Consequently, it becomes necessary to fill the void in

the top of the collet with a filler or collet life plug. This is a practical

solution to avoid collapsing of the collet, which may result from not following

the 80% rule. (Figure 3)

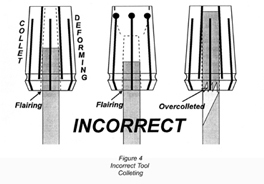

In all router bits, there is an area known as the flute fadeout section of

the tools.

This is formed when the grinding wheel utilized in the manufacturing

of the tool exits the work piece. In order to properly collet a router

bit, the mouth or bottom of the collet must contact the router bit slightly

above the flute fadeout. Overcolleting or allowing the flute fadeout portion

to extend inside the collet can damage the collet and is a common cause

of tool breakage. (Figure 4)

This is formed when the grinding wheel utilized in the manufacturing

of the tool exits the work piece. In order to properly collet a router

bit, the mouth or bottom of the collet must contact the router bit slightly

above the flute fadeout. Overcolleting or allowing the flute fadeout portion

to extend inside the collet can damage the collet and is a common cause

of tool breakage. (Figure 4)

Collet Maintenance

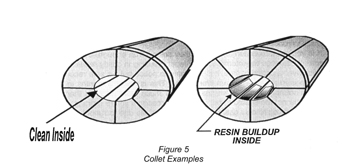

Router bits and collets are expected to operate accurately in a work

environment inundated with heat and grime.

Plastic chips formed by the

cutting action of the router bit carry with them resins that migrate through

the slits of the collets and adhere to the inside of this closely toleranced

mechanism. The resin build up usually concentrates

nearest the mouth of the collet. At this

point, the tool is no longer being equally gripped

causing a loss in concentricity and tool run out.

Once again, the lack of a router tool running in a

true circle effects the finish of the part and may

cause the ultimate demise of the tool. (Figure 5)

Plastic chips formed by the

cutting action of the router bit carry with them resins that migrate through

the slits of the collets and adhere to the inside of this closely toleranced

mechanism. The resin build up usually concentrates

nearest the mouth of the collet. At this

point, the tool is no longer being equally gripped

causing a loss in concentricity and tool run out.

Once again, the lack of a router tool running in a

true circle effects the finish of the part and may

cause the ultimate demise of the tool. (Figure 5)

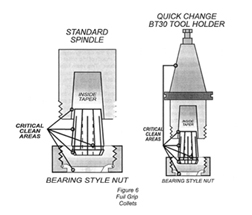

Fortunately, this problem is easily resolved by

cleaning the collets after every tool change. The

procedure involves the use of non-abrasive

brass tube brush applied inside the collet in

combination with a cleaner such as Rust Free.

All surfaces inside and outside the collet, inside

the spindle taper, and matching and mating surfaces

of quick-change toolholders, should be

thoroughly cleaned and dried before being

reassembled.

Also, the collet nut should be

cleaned of resin and chip buildup and regularly

replaced to insure the integrity of the whole collet

system. (Figure 6)

Also, the collet nut should be

cleaned of resin and chip buildup and regularly

replaced to insure the integrity of the whole collet

system. (Figure 6)

Collet Replacement

Collets are manufactured from spring steel and

regular usage causes a loss of elasticity.

Therefore, it becomes necessary to replace collets

on a regular interval as a part of an ongoing

maintenance procedure. With diligent attention

to proper collet maintenance, the average collet

should be replaced about every 400-600 hours

of run time. Avoiding regular replacement can

lead to brittle collets, which may crack or break,

and cause permanent damage to the spindle.

Replacement of collets is a much more economical alternative

than replacing router bits or expensive spindles.

Rigidity and concentricity are the key elements in any routing

application. The simple process of properly colleting router tools,

maintaining collets, and replacing them at regular intervals will

safeguard the productivity of the operation and insure that the finish

of plastic parts is not jeopardized.

For more information, click on the Author Biography link at the top of this page.

|