|

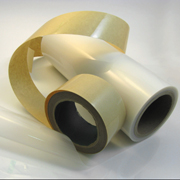

PVDF Film

PVDF (Kynar®) is strong and

tough as reflected by its tensile

properties and impact

strength. Compared to many thermoplastics,

PVDF has excellent

resistance to creep and fatigue,

yet it is flexible and transparent.

It is stable to UV and the effects of weather, has low NBS,

and has an excellent transmittance of solar energy. Kynar

can withstand temperatures up to 265°F, has a VTM-0

UL94 Rating and excellent chemical resistance. It can be

used in filters, fuel cell seals, medical bags, diaphragms,

release films, piezoelectric films and chemical-resistant

tank linings. Its also a possible substitute for Tedlar®.

CS Hyde stocks .003” through .020” PVDF film. It is

sold by the lineal foot with no minimums. Slit rolls and

Die-cut parts are available.

strength. Compared to many thermoplastics,

PVDF has excellent

resistance to creep and fatigue,

yet it is flexible and transparent.

It is stable to UV and the effects of weather, has low NBS,

and has an excellent transmittance of solar energy. Kynar

can withstand temperatures up to 265°F, has a VTM-0

UL94 Rating and excellent chemical resistance. It can be

used in filters, fuel cell seals, medical bags, diaphragms,

release films, piezoelectric films and chemical-resistant

tank linings. Its also a possible substitute for Tedlar®.

CS Hyde stocks .003” through .020” PVDF film. It is

sold by the lineal foot with no minimums. Slit rolls and

Die-cut parts are available.

It is also available with pressure

sensitive adhesive.

It is also available with pressure

sensitive adhesive.

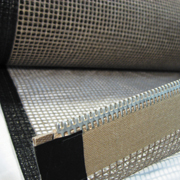

PTFE Belts

Energy costs are sky-rocketing.

If you are looking for ways to

reduce energy costs, consider

PTFE coated belting versus stainless

steel or modular plastic. They

provide energy savings, with better

heat transfer and less energy

absorption, have lower maintenance

costs, are non-stick and

easy to clean and are less expensive. They can be operated

using simpler, less expensive pulley and drive systems.

For more information, contact Tiffany Hoerld, CS

Hyde Company, 1351 N. Milwaukee Ave., Lake Villa, IL

60046, 800-461-4161, Fax: 800-441-8063, E-mail:

sales@cshyde.com, Web: www.cshyde.com.

|