|

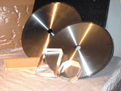

Saw Blades Spotlight

Non-Melt Saw Blades

Non-Melt Saw Blades

Amana Tool’s non-melt saw blades

are designed to

produce crisp,

clean cuts in

acrylics such

as Plexiglas®

and Lucite®,

polycarbonates

such as

Lexan® and

other plastics.

The non-melt blades are designed with a modified

triple-chip grind (MTCG) and 2° negative hook angle that

produce less heat than standard saw blades, eliminating

“chip-welding” or melted materials.

Amana’s saw blade bodies are laser cut from virgin

steel, annealed for accurate tooth alignment, and roll tensioned

to ensure straight cutting performance. Carbide

tips are manufactured and ground to Amana’s specifications,

enabling smooth, accurate cuts and longer-lasting

cutting performance between sharpenings. The blades

feature laser-cut expansion slots and copper plugs to

reduce noise and minimize vibrations, as well as prevent

heat buildup and blade warping.

Amana’s collection of non-melt blades are available in a

diameters ranging from 8” to 16”. For example, item

LB10801 has a 10” diameter and 80 teeth.

For additional information, contact Frank Misiti, Amana

Tool, 120 Carolyn Blvd., Farmingdale, NY 11735, 800-

445-0077/631-752-1300, Fax: 631-752-1674, E-mail:

frankm@amanatool.com, Web: www.amanatool.com.

TCG Saw Blades

AWED

offers plastic

cutting saw

blades with

the unique

triple-chip

grind (TCG)

tooth design.

It's design

offers a cut

unequal by

any other

blade. These blades can be used on standard table saws

or panel saws, manual or CNC. A variety of sizes are available

to meet your specifications.

AWED

offers plastic

cutting saw

blades with

the unique

triple-chip

grind (TCG)

tooth design.

It's design

offers a cut

unequal by

any other

blade. These blades can be used on standard table saws

or panel saws, manual or CNC. A variety of sizes are available

to meet your specifications.

For additional information, contact Victor Miranda, AWED

Corp., 1175 Buford Highway, Suite 101, Suwanee, GA

30024, 770-831-9800, Fax: 770- 831-7404, E-mail: victor@awedmachine.com, Web: www.awedmachine.com.

General Purpose & Precision Saw Blades

General Purpose & Precision Saw Blades

Craftics

provides

a variety

of tools

and

accessories

for working

with

plastics,

including

Tenryu Saw Blades. They inventory the Tenryu Plasti-Cut

and Pro Series Blades for Plastics in a variety of sizes and

grades.

The Plasti-Cut blades are designed for general purpose

cutting on a variety of materials and material thickness.

High-grade carbide teeth and an ultra-thin kerf will allow

faster feeding and minimal waste. They provide exceptional

performance for a value price. Craftics offers 7-1/4”,

10”, 12” and 14” diameters from stock.

The Pro Series blades are superior quality, high-precision

blades that offer fine-grain, wear-resistant carbide

teeth for long life, expertly tensioned steel bodies for

true and accurate cuts, built-in expansion slots act as

dampeners to reduce vibration and noise. Achieve precise

professional cuts in production applications time

after time. Craftics offers 10”, 12” and 14” diameters

from stock.

Craftics also offers the Craftics Brand Plasticutter and

Edgescraper and Onsrud Cutter Router Bits and can

sharpen your saw blades.

For additional information, contact Tracy Pineda,

Craftics, 2804 Richmond Drive NE, Albuquerque NM

87107, 866-296-2130, Fax: 800-289-2020, E-mail:

sales@craftics.com, Web: www.craftics.com.

No-Melt Blades for Cutting Plastics

No-Melt Blades for Cutting Plastics

Modified triple-chip-grind

tooth style and specially

engineered side clearances

make Forrest

Manufacturing’s carbide tipped

No-Melt blades

the perfect choice for cutting

single or multiple

stacked sheets of plastic

without chipping or melting.

The No-Melt blade is just one or the many award-winning

general-, special- and custom-purpose blades and

dados offered by Forrest Manufacturing, a family-owned

business for more than 50 years. All Forrest blades are

manufactured in the U.S. to exacting standards, using proprietary

grinding techniques and hand straightening. The

result is exceptional perimeter concentricity, an astonishing

+/- .001-inch side runout and super fine tooth grind

for smooth, quiet and precise cuts.

The No-Melt blade is no exception. Its numerous teeth

allow fast feeding of brittle acrylics. Super-hard C-4 micrograin

carbide tips ensure 50 to 300 percent longer life

between sharpenings.

The No-Melt blade is available in 7- to 20-inch diameters

with 60 to 120 teeth. It’s particularly appropriate for

cutting acrylics, delrins, ABS, styrenes, PVC, and high- and

low-melt nylons.

Every Forrest blade comes with a 30-day money-back

guarantee. Factory sharpening services are provided at

reasonable cost.

For additional information, contact Jay Forrest, Forrest

Manufacturing Company, 457 River Road, Clifton, NJ

07014, 800-733-7111, Web: www.forrestblades.com.

High Performance Saw Blades

High Performance Saw Blades

FTM, Inc. offers a line of General Saw’s high performance

carbide-tipped circular saw blades. General Saw has specialized

in the design and manufacture of blades specifically

for the cutting of plastics, woodworking, solid surface

and non-ferrous metal industries. Since 1937 they have

been manufacturing standard and custom saw blades

designed specifically with your cutting needs in mind. For

aluminum plate, plastic extrusions, foam board, polycarbonate,

low-melt acrylic, melamine, veneers, trusses and

more. General Saw has engineered a blade that is right for

you. They recognize the importance of the careful selection

of fabricating materials, the differences in blade

design, required machines and techniques needed to produce

and test their products for successfully cutting various

plastics and have acquired the latest of these important

component. General Saw has helped companies and

individuals across the world, and right next door, get the

most out of their material and their machines by offering

a superior cutting blade.

For additional information, contact Robert Ashcraft,

FTM, Inc., 327 Industrial Drive, Unit 1, Placerville, CA

95667, 530-626-1986, Fax: 530-642-2602, E-mail:

info@123ftm.com, Web: www.123ftm.com.

Onsrud Adds Saw Blades for Plastics

Onsrud Adds Saw Blades for Plastics

Fabricators of plastic

material know to turn

to Onsrud Cutter for

their routing tools.

These same fabricators

can now turn

to Onsrud for their

sawing needs as

Onsrud has introduced

a line of 8”,

10” and 12” blades for

plastic materials including

acrylic,

derlin, ABS,

styrene, PVC and nylon

The line offers premium performance

resulting in cool, clean cutting of

plastic without chipping or melting.

The saw blades are designed to be

used on table, miter and panel saws.

Onsrud Cutter is the only cutting

tool facility in the United States that

manufactures high-speed steel, carbide

tipped, solid carbide, diamond

coated and PCD CNC router tooling.

Onsrud manufactured their first

router bit in 1920.

For additional information, contact

Leslie Banduch, Onsrud Cutter LP,

800 Liberty Drive, Libertyville, IL

60048, 847-362-1560, Web: www.

onsrud.com.

|