|

PLASTIC WELDING: Plastic Welding Q & A

Q: How does one determine the proper thickness and reinforcements for a plastic tank?

A: Tanks can be reinforced from the outside with ribs or frames. This can be done with the same material as the tank, FRP (fiberglass reinforced plastics) or even steel. When the same plastic material is used, the welds should be placed where the bending movements are low. The design may change, when the reinforcement materials show a different temperature expansion than the material used to build the tank. The supports might change in dimensions, even if they are on the same tank, but because of the different pressure and stress areas on the tank walls, the reinforcement shapes could change. Temperature changes and used plastic material may be an issue as well.

Unfortunately, there is no quick and easy answer to the question.

Is the tank a pressure tank? Is it a tank with rounded corners? Does the tank has a uniform wall thickness?

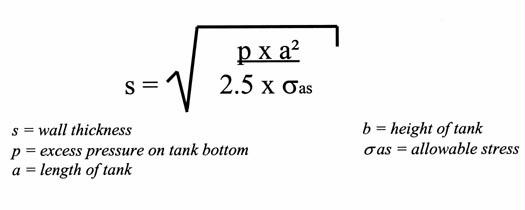

Here is a short and easy formula for a tank wall thickness without reinforcements and a side ratio a/b < 0.5:

This is just one of many calculations to perform.

It gets really interesting and complicated when your tank differs in shape. The container could be round, oval, square and rectangle or even odd-shaped.

The calculations get very complex when you add supports.

More than 20 different values are needed to make the proper calculations. Some values can be found in different charts. Other values can be taken from calculations and the specific application itself.

Too many factors are involved which makes it impossible to give a simple or general solution for these kinds of challenges. But, it is not hopeless. Published formulas with detailed descriptions are available from the German Welding Society (DVS) at www.dvs-ev.de/en. They will help you find the calculations that will fit to your specific application.

Q: Why is the plastic part I am manufacturing cracking so easily?

A: There are many reasons why plastic materials crack. Factors include where the fractures occur and what you define as a crack. Is it a deep crack or are these hairline cracks? What is the manufacturing/fabricating process?

Most likely the problem is related to stress inside the plastic material. Some materials are more affected by stress than others. Nevertheless, stress is a main factor. Here are some reasons for cracking:

- The part is not designed properly - a minor change might work wonders.

- The plastic material is contaminated either with other plastic resin or debris.

- The processing times are too short or too long.

- The processing temperature is too high, which might cause degraded and brittle parts.

- The material wasn’t tempered prior to the fabrication process. Some plastics (e.g. PMMA) require this step.

- The tools used are not appropriate. They could be dull or too slow.

- Chemicals have attacked the plastic parts - possibly for cleaning purposes or mold releases.

- Drilled holes and/or cutouts add stress.

- Improper handling such as banging or dropping.

- Wrong storage. Temperature fluctuations, humidity or UV influence while storing could have an effect on the product.

These are the main causes why fabricated plastic parts crack. You can find others, but if you try to eliminate these first, you’ll likely be successful. |