|

PLASTIC WELDING: Fabrication of Plastic Parts

Prior to fabricating large or small plastic parts, you must familiarize yourself with the materials you will be working with and their requirements. You will also need to understand the customer’s wishes and/or needs and make sure they are realistic. The right assembly equipment is also important in order to be efficient and provide a quality, competitively priced product. The equipment you will need is dictated by the volume and part design and also dependent on the plastic materials.

Fabricating plastic parts looks easy, but if you review my previous articles, you know that problems can occur. Every plastic material has different physical and chemical properties. To review, there are basically three groups of plastics polymers structures.

- Amorphous

- Crystalline

- Partially (or Semi-) Crystalline

Amorphous polymers are softer and have lower melting points. Solvents can penetrate easier than with their crystalline counterparts.

Crystalline polymers are rigid and have a higher melting point. They are less affected by solvent penetration. These polymers are strong, but they show a lower impact resistance.

Partially (or Semi-) Crystalline polymers have regions of amorphous and crystalline structures. These plastics combine the strength of crystalline polymers with the flexibility of the amorphous polymers.

This little excursion into plastic chemistry shows that the purpose of the product needs to be known before the fabrication can be done. You cannot use an amorphous plastic if solvents are involved without having trouble.

After the desired material is found, the design of the part is next. Each weld can be a weak spot. Therefore, try to eliminate unnecessary welds. This will save time and money.

To build a tank, static calculations need to be done. These are important to make sure that the finished product is capable of meeting the stress of the load. Remember that a tank filled with a liquid (or solid) substance has to hold more pressure the larger the container gets. It is too extensive to explain the mathematics, because they are dependent on the size and shape, plastic material, process temperature, and designation of the usage. These calculations should be left to engineers and experienced fabricators.

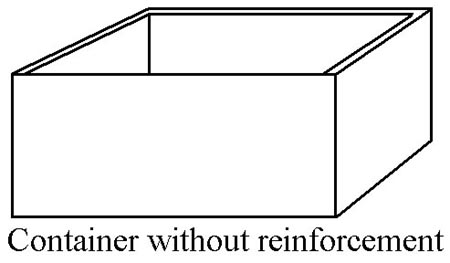

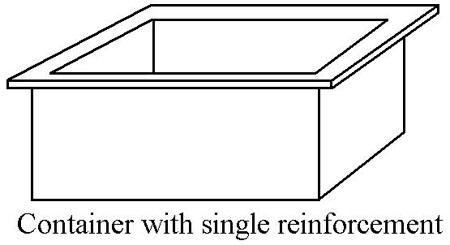

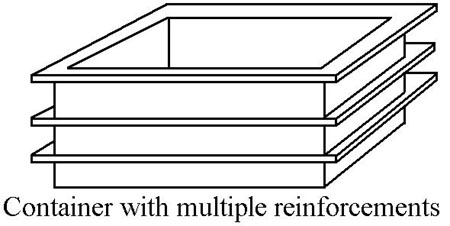

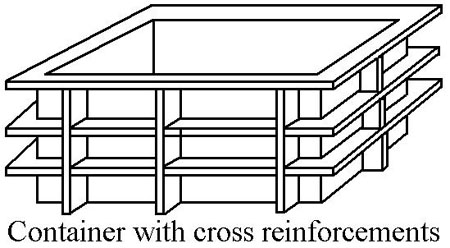

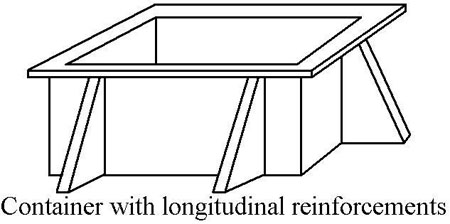

To reduce the stress on the walls and increase strength of square tanks, for example, you can use different reinforcements as seen in the following five examples.

Normally, the above reinforcements are made out of the same material as the tank or container. This will ensure that you can weld the supports directly on the tank.

If you know that the end use of the product is to contain harmful substances, you should consider building some safety features such as secondary collection areas. Authorized welders should only perform the welding on these parts. Generally speaking, every container that contains material that could be harmful, needs to be built by a certified person.

Not all containers or tanks or other apparatuses are subject to these strict regulations so there is a lot of work left for fabricators in custom manufacturing.

Fabrication starts with material selection. After you know what kind of plastic is to be used, and the dimensions are determined, you can determine what equipment you will need to use. The tools you may want to use are not always available. This may lead to the purchase of new machines. As mentioned before, the amount of work will dictate the tooling. To produce lots of long straight welds to join sheets together, a Sheet Butt Welding Machine would be very efficient. This machine works like a hot plate welder. Two sheets (usually PE or PP) get fixed with multiple clamping devices in the machine. A long hot plate is positioned between the sheets. Pressure is applied on the sheet material against the plate. After a melt occurs, the pressure is released and the plastic sheets rest against the hot plate to allow the heat to travel inside the material. After the prescribed period of time, the sheets get separated from the hot plate, the plate is removed and the sheets get pressed firmly together. This process is according to a chart for hot plate welding. Good sheet butt-welding machines are pre-set for standard materials and thickness. These machines work great, but they are not cheap and they are fairly large. This illustrates how the number of welds can justify the purchase of such a machine. For less welding, an extrusion or injection welder can do a fine job. It will take longer, but it is less expensive.

To reduce the amount of welding, other interesting machines can be used. One is a Sheet Bend-Welding Machine and the other is a Sheet Bending Machine. These tools work similarly. The Sheet Bend-Welding Machine melts into the plastic with a wedge-shaped heated bar, the Bending Machine preheats the plastic sheets with two heated wires from both sides. The sheets will be positioned on the equipment and heated. When the sheets are ready to bend, they will be moved to the bending section on the machine. The sheets can be formed now to a pre-adjusted angle. Which of these two machines to choose depends on the material. If you work mostly with PVC, PMMA or ABS, I would recommend the bending unit. If you work more with PE or PP, I prefer the bend-welding machine. In either case, the number of welds is reduced.

As a reminder, every weld should show a root bead. If it is not possible to weld from both sides, the weld zone should be baffled out in an angle of 60º-70º for all hot air and extrusion welders, 80º-90º for injection welders. Also the three parameters Temperature, Pressure and Time must be in the specifications at all times.

So, in order to build a tank, it is best to weld the inside and the outside. Because the tank should be water tight, the inside welds should be done from the corners away. The corners are the most critical areas to weld (see Drawing 6). The most common welding tools to create these welds are injection welders, which are easy to use and offer high quality welds, Extrusion welders for their high output and weld quality, and Stick welders. Stick welders should only be used for smaller parts or to make the root beads for extrusion welders.

.JPG)

Some might say that you would have more starting and end points this way. This is correct and I agree that it bares the danger to produce failures. But I contend that it is easier to meet on a straight area than it is in the corners. If the person who produces the weld takes care and knows what he or she is doing, the chances of producing a watertight tank are higher.

Fundamentally, the more you prepare, the more efficient and successful you will be. The above are basics and should be used as a starting point. My intention is to bring you another step closer to understanding plastics and the differences in the materials, as well as how to fabricate a quality product. In the end, it all depends on the person who does the work and the quality of their skills.

For more information, click on the Author Biography link at the top of this page.

|